In 1965, Department No. 8 was established as the Department of Chemistry of Sulfolanes. The priority areas of the Department’s activities were the study of the reactivity of five-membered cyclic sulfones, the development of new methods for the synthesis of their derivatives, a comprehensive study of the chemical and biological properties of new substances and their practical use in production. From 1965 to 1986, the Department was headed by Tamila Eduardivna Bezmenova, Doctor of Chemical Sciences, and from 1986 to 2002 by Anatolii Oleksandrovych Hryhoriev, Doctor of Chemical Sciences, under whose leadership the Department of Chemistry of Sulfolanes was renamed into the Department of Organic and Petrochemical Synthesis. Anatolii Oleksandrovych Hryhoriev was the initiator of this transition, aligning with the new tasks of the Department, although the research in the field of the chemistry of sulfolanes remained prioritised. From 2003, the Department was headed by Volodymyr Illich Kashkovskyi, Candidate of Chemical Sciences, who initiated a new direction for the Department, which involved the study of metathesis and co-metathesis reactions with the aim of creating new methods for obtaining valuable products from petroleum. From 2021, the Department has been headed by Vitalii Oleksandrovych Yevdokymenko, Candidate of Chemical Sciences. In 2022, Laboratory No. 8.1 of Polymer Modification, headed by Sergey Petrovich Rogalsky, Candidate of Chemical Sciences, joined the Department.

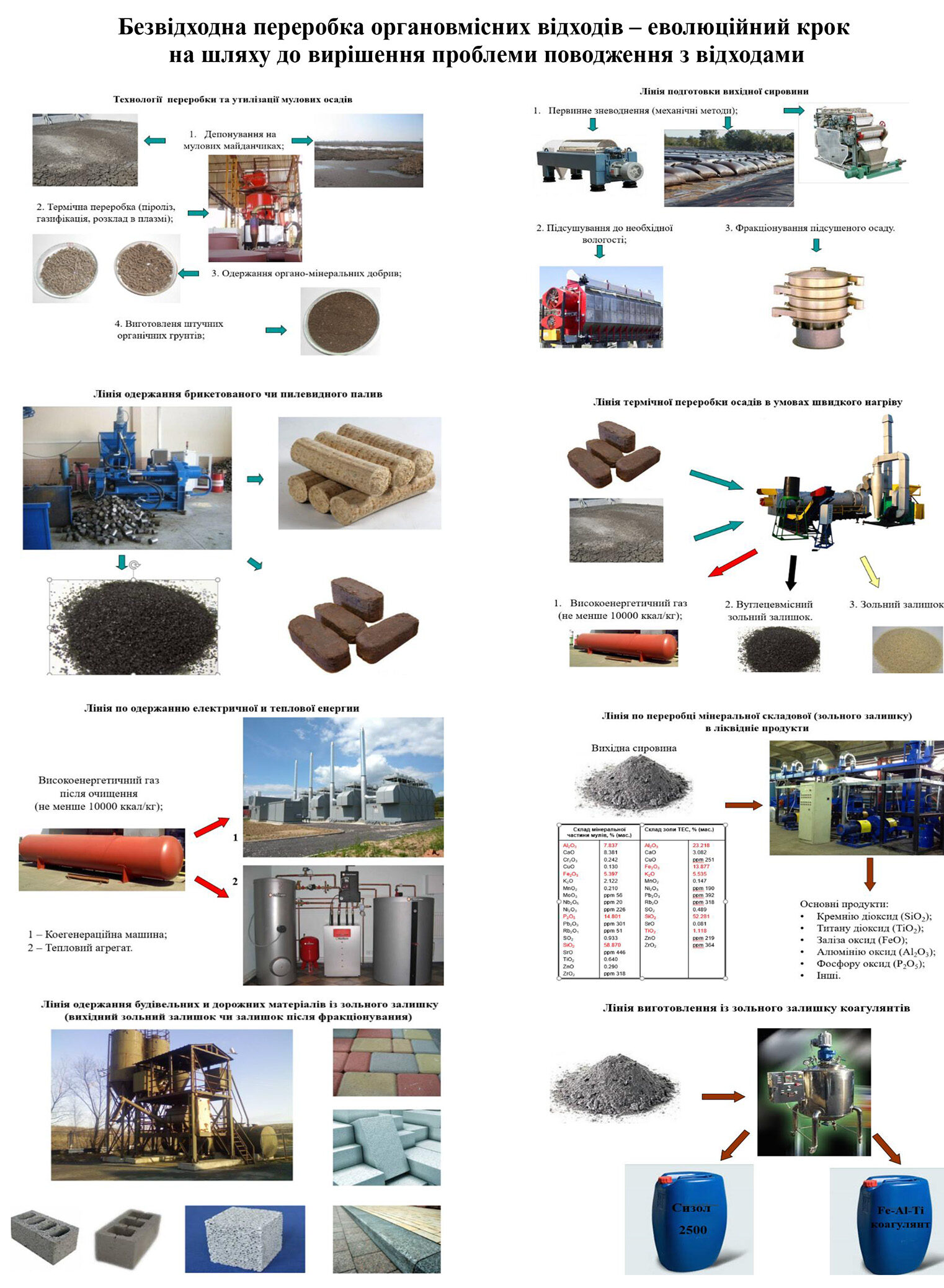

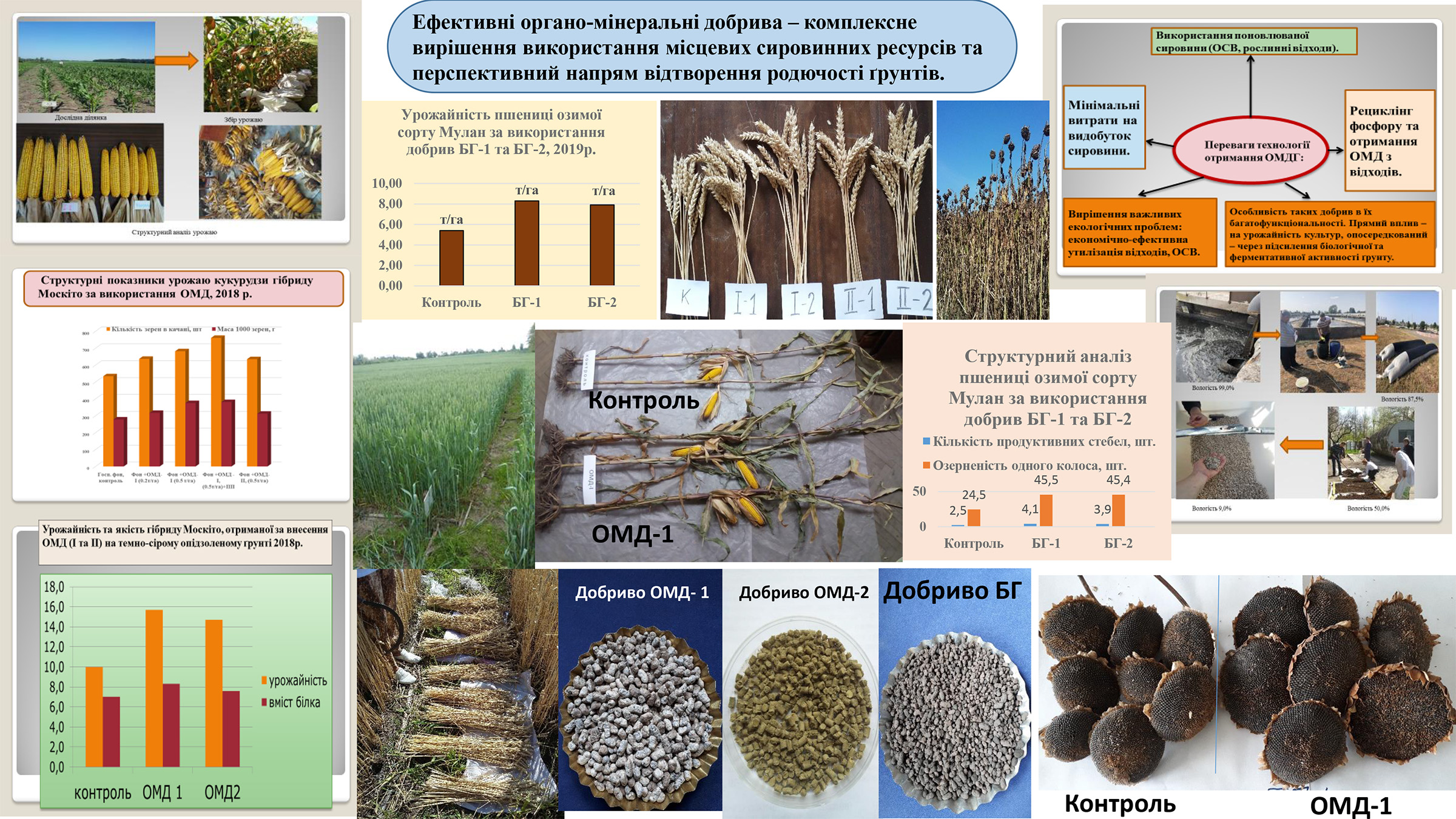

The Department of Organic and Petrochemical Synthesis conducts fundamental and applied research in the field of petrochemistry and green chemistry. The main areas of activity of the Department are related to the processing of carbon oxides on industrial catalysts to obtain alcohols and motor fuel components; research into the metathesis and co-metathesis reactions of various substances to develop new methods for the production of valuable products from petrochemical and plant raw materials; research into the scientific and technical aspects of key stages in the technological process of processing plant biomass and anthropogenic waste to obtain chemical reagents as basic products, and as precursors for obtaining organic synthesis products; development of organo-mineral fertilisers and primers from anthropogenic and agricultural waste; synthesis and research of multifunctional modifying additives based on plant and petrochemical raw materials for industrial polymers; research of fullerenes, toroidal organoelement clusters and bimetallic coordination compounds in radical oxidation reactions of organic substances. Within the scope of competitive topics, the Department conducts work on the creation of modern, practical methods for obtaining cellulose with maximum crystallinity by biomass conversion, research on the production and accumulation of hydrogen during the operation of a reversible fuel cell in direct mode and the generation of electric current in reverse mode, scientific research and development of technical aspects of converting the potential of sediments into components of flocculants, building materials and organo-mineral fertilisers, development of formulations and technologies for the creation of complex organo-mineral fertilisers in granulated form with prolonged action based on ash residues, excess sludge, processed plant waste, humic components to improve mineral nutrition, in particular phosphorus, of major cereal crops (winter wheat and corn), development of formulations for blended ethanol biodiesel fuels from domestic agricultural raw materials.

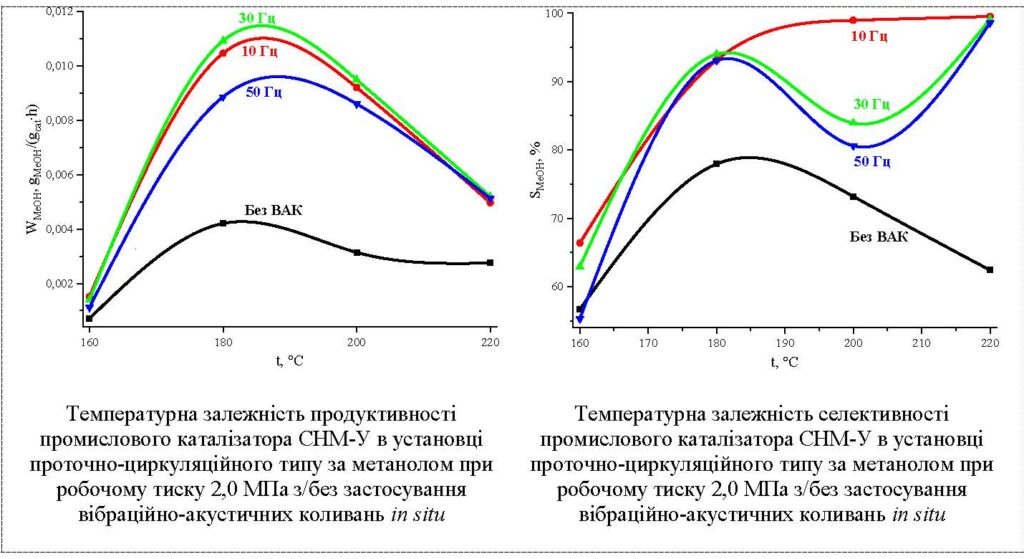

The laboratory setup for the hydrogenation of carbon oxides on the industrial catalyst CHM-U, utilising vibration-acoustic oscillations, has been improved. Tests were performed at different temperatures and pressures of a mixture of carbon oxides with hydrogen in the reaction of methanol production in a comparative aspect of two main research modes: using the method of dynamic catalysis through the influence of low-frequency vibration-acoustic oscillations and industrial synthesis of methanol without in situ activation. It has been shown that the use of vibration-acoustic oscillations contributes to an increase in catalyst activity and maintenance of this state over time. During experimental studies, optimal operating conditions for the catalyst with an extended inter-regeneration cycle were established. Recommendations for technological modes of process management and the development of a basic technological scheme for the processing of carbon oxides into important chemical products under the influence of acoustic vibration fields were formulated.

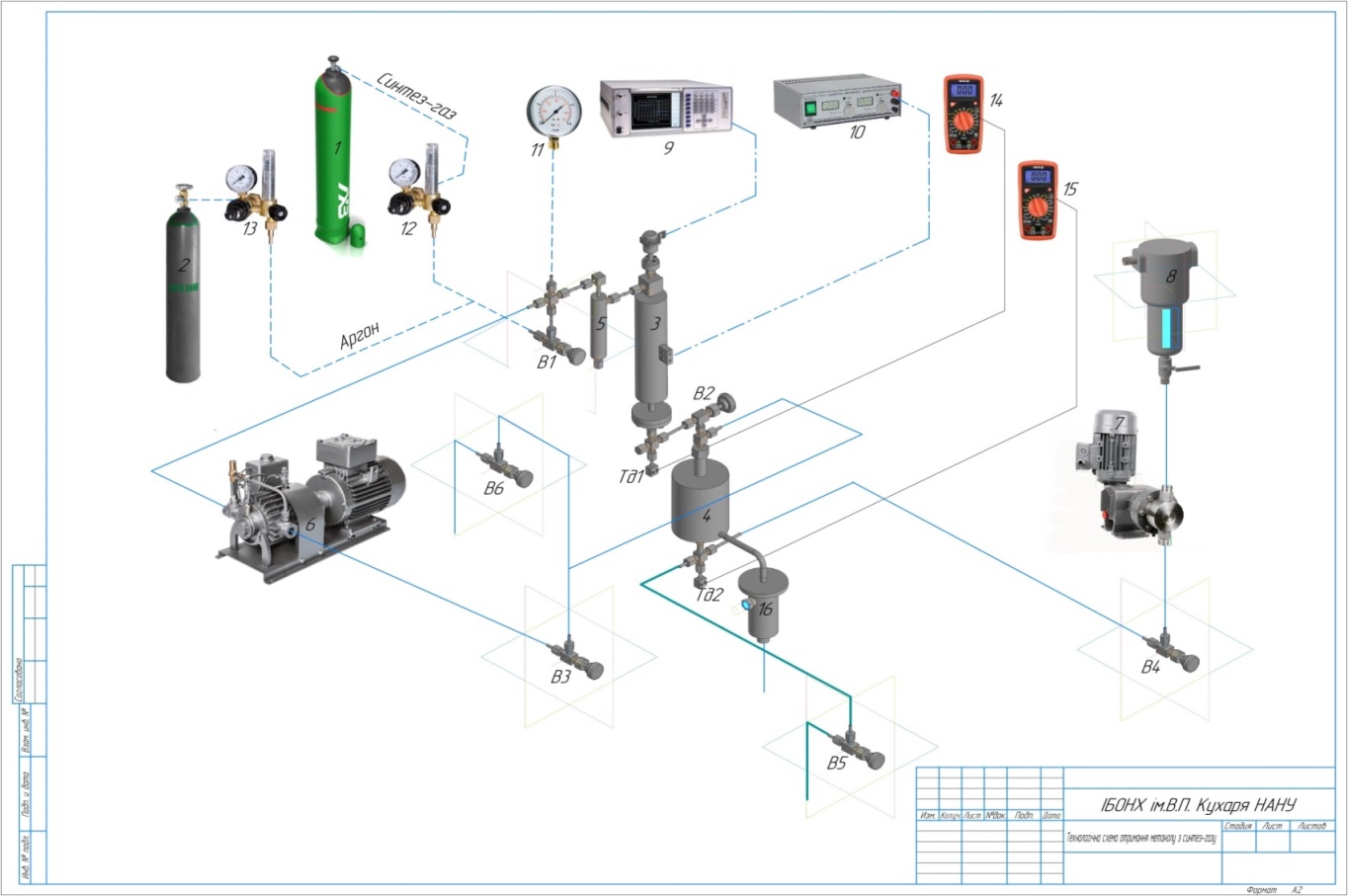

Schematic diagram of the laboratory setup: 1, 2 – cylinders with compressed gases (working mixture and argon, respectively); 3 – reactor; 4 – combined separator with a Peltier cooling system; 5 – gas purification system; 6 – circulation pump; 7 – metering pump for the capture mixture; 8 – container with the capture mixture; 9 – generator with a power amplifier for vibration-acoustic oscillations; 10 – electric reactor heater; 11 – pressure gauge; 12, 13 – reducers; 14 – temperature control sensor in the reaction zone; 15 – temperature control sensor in the cooling zone; B1–B6 – fine control valves.

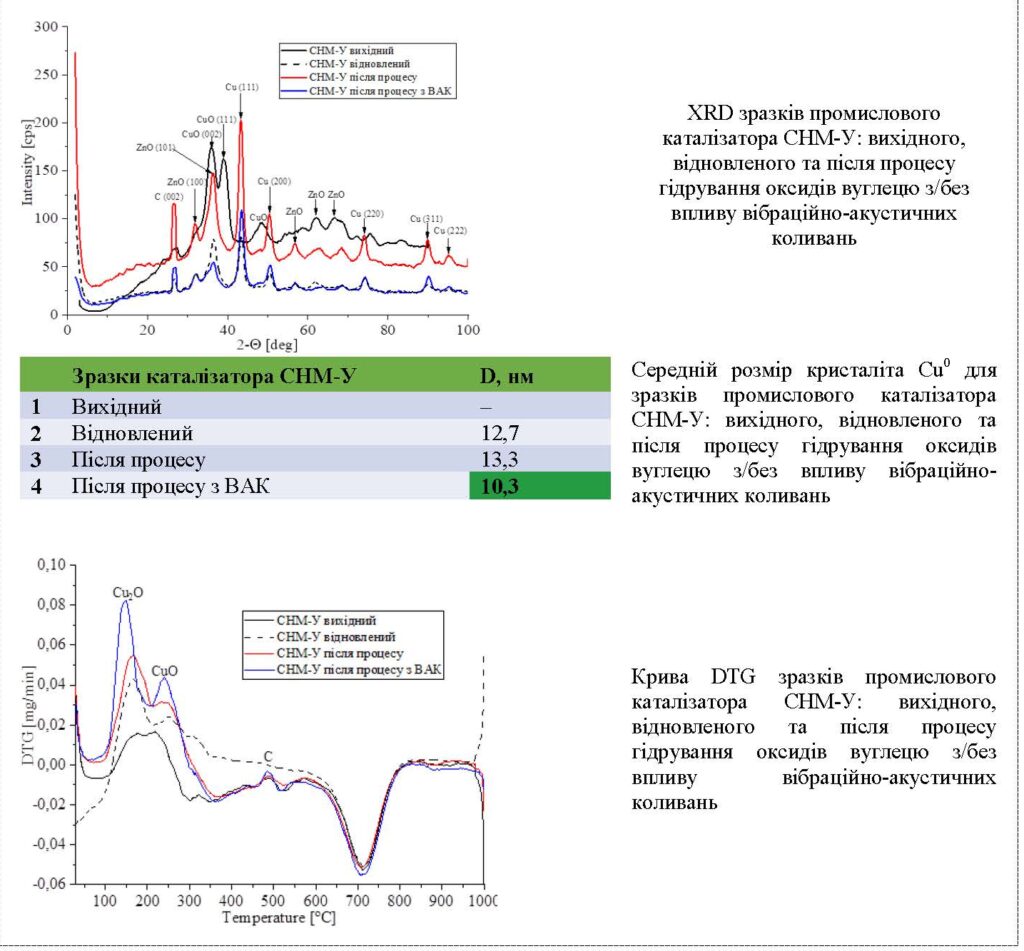

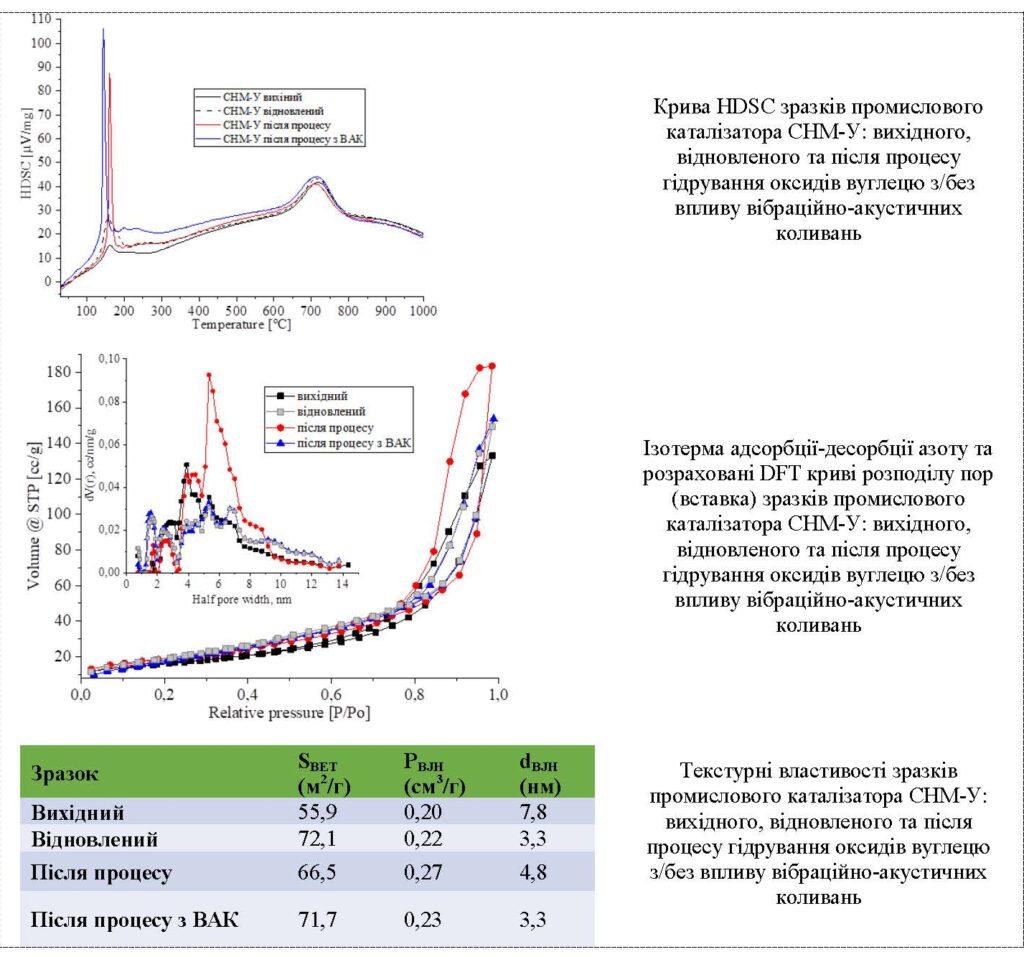

A complete comparative physical and chemical analysis of an industrial catalyst before and after the hydrogenation of carbon oxides was performed. It was established that the following structural and morphological characteristics influence the increase in the activity of the CHM-U catalyst: the average size of copper crystallites, the morphology of the catalyst surface, its specific surface area, and thermogravimetric characteristics.

A series of comparative studies of the catalytic characteristics of the industrial granulated catalyst CHM-U using a working gas mixture (mole ratio CO : H2 : CO2 = 1.0 : 2.92 : 0.24) of carbon oxides with/without the use of vibration-acoustic vibrations in situ was carried out. The results of the studies showed that the use of in situ vibration-acoustic oscillations with a frequency of 30 Hz in the hydrogenation of carbon oxides contributes to a 2.6-fold increase in the productivity of the SNM-U catalyst with methanol while increasing selectivity by 16%. The hydrogenation process under in situ vibroacoustic vibrations showed that this is one of the promising factors influencing the increase or maintenance of the activity of existing industrial catalysts during the process.

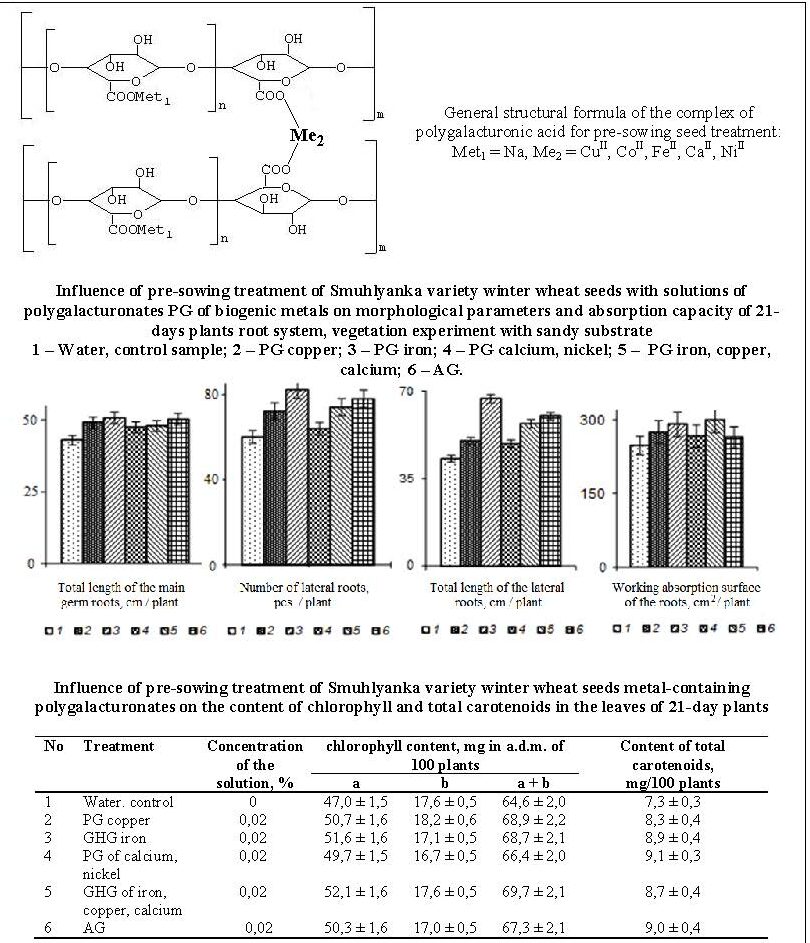

The effectiveness of compositions consisting of nano-silica, polymetallic complexes of polygalacturonates of biogenic elements with lignohuminic and lignosulfonate components for priming spring wheat seeds in a field experiment based on the structural unit ‘Agrobiostation’ of the Mykola Gogol State University of Nizhyn. The use of such combined preparations of organic origin for pre-sowing seed treatment stimulates germination energy by 19-28% and activates the growth and development of experimental spring wheat plants. Under conditions of insufficient moisture supply during the germination period and elevated temperatures during the growing season, the compositions used in the experiment for priming wheat seeds contributed to the formation of a powerful physiologically active root system with improved morphological indicators, which had a positive effect on the processes of moisture absorption and assimilation of nitrogen, phosphorus, and potassium from deeper soil layers. The use of silver polygalacturonate with active silicon in a nanocomposite for priming in the experiment contributed to an increase in grain productivity of a single wheat plant by 21%, which allowed for a grain yield increase of 1 t/ha compared to the control. The introduction of potassium humate with silver polygalacturonate in the complex provided a grain yield increase of 0.8 t/ha compared to the control. Testing of nanocomposite preparations based on heterometallic complexes of polygalacturonates of biogenic elements, nano-silica, lignohumic and lignosulfonate components showed their potential for use in stimulating seed germination and increasing plant productivity. Field studies allow us to conclude that the examined nano-complexes have a multifaceted effect on plants: they activate bioenergetic processes, stimulate root growth, enhance the penetration of mineral elements and improve the nutrition of spring wheat plants. The need to improve modern agricultural technologies through the use of the latest domestic innovative products of organic origin will reduce the costs of their purchase and implementation and will be offset by increased yields.

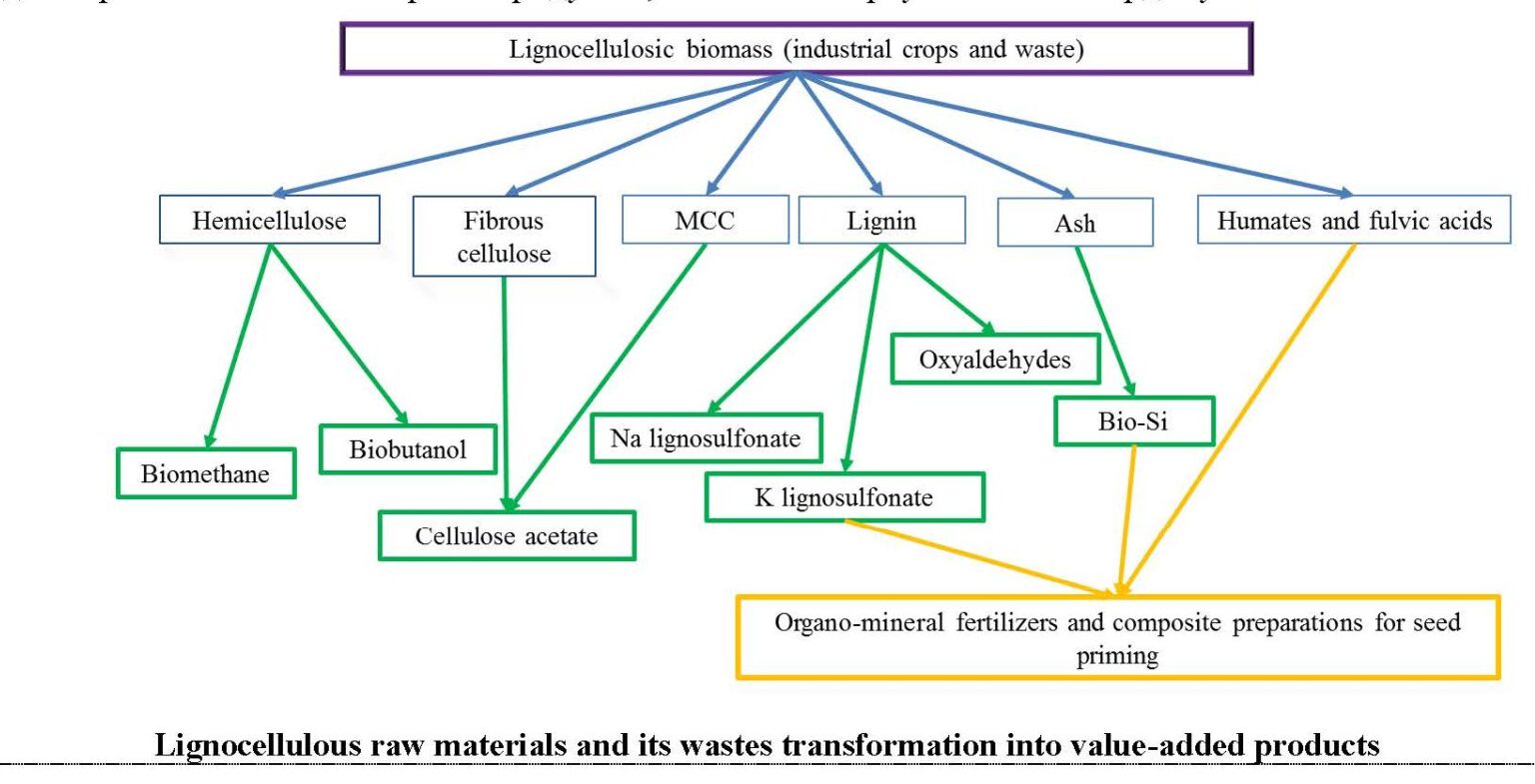

A chemical analysis of lignocellulosic raw material waste was performed, namely tree crowns (poplar, oak, birch, linden, chestnut, maple), green waste from mowing lawn grass and mixed grasses, fallen leaves (poplar, oak, birch, linden, chestnut, maple) and technical crops (giant miscanthus, sugar and Chinese miscanthus, sugar sorghum, flax and hemp). It has been established that the waste is characterised by a high content of water-soluble substances and hemicellulose, which makes it attractive for further processing by bacteria. At the same time, industrial crops are more attractive for obtaining cellulose, which is currently a pressing issue for our country. It has been shown that the highest yields of fibrous cellulose and MCC ≥90% are achieved when processing technical hemp fibre of the Glesia variety. Such products were characterised by a low content of inorganic components (0.5 and 0.2%, respectively) and lignin (1.6 and 0.8%, respectively). Sodium and potassium lignosulfonate were obtained from lignin extracted from the cooking solution for the production of cellulose products. The latter was used to produce fertilisers that successfully passed field trials. Sodium lignosulfonate is widely used as a binding agent in metallurgy. Cellulose acetate was produced from the cellulose products obtained, which is similar in its characteristics to industrial samples. Thus, the studies showed the possibility of wide application of lignocellulosic raw materials for obtaining a number of commercial products that are currently imported from abroad.

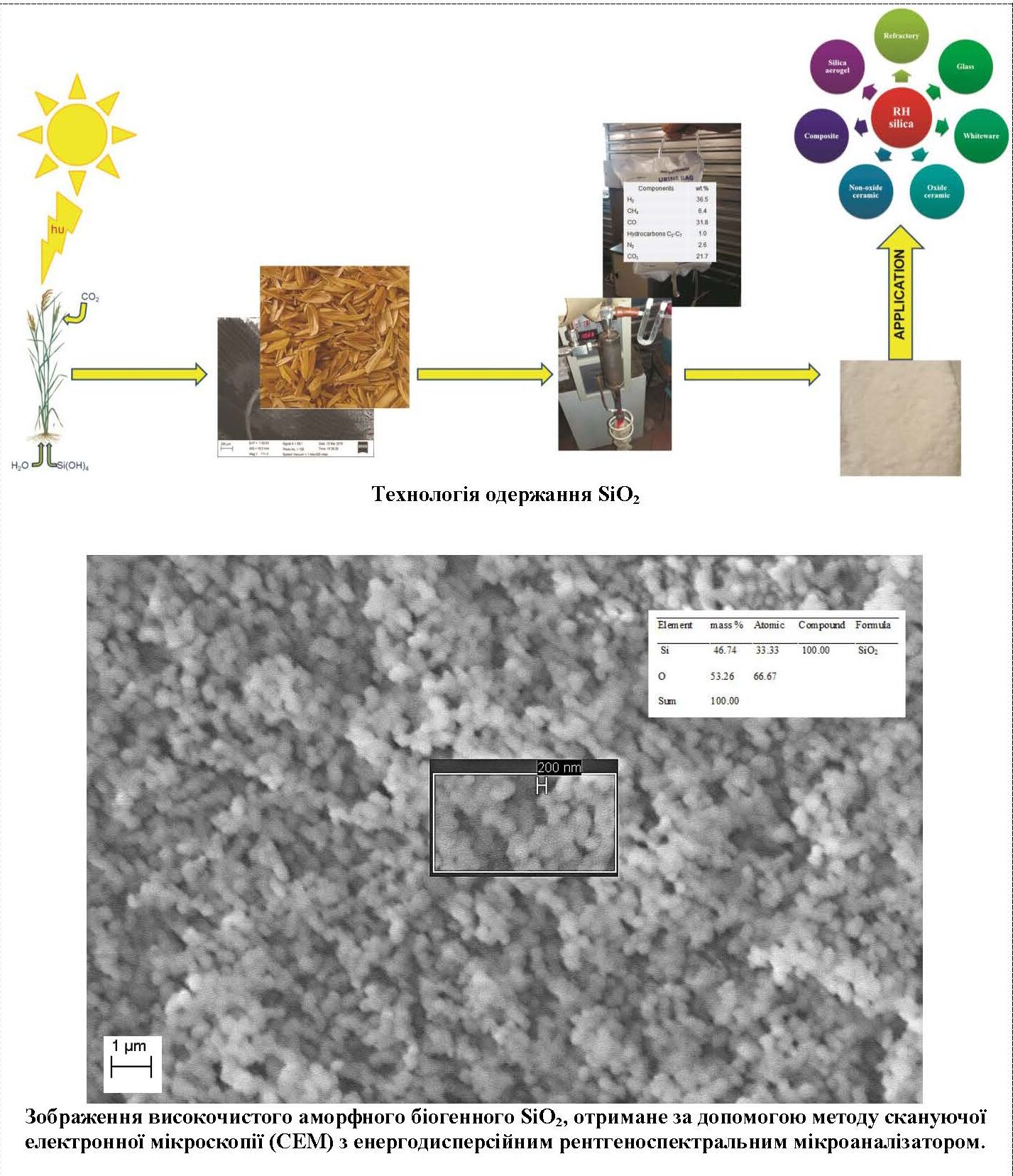

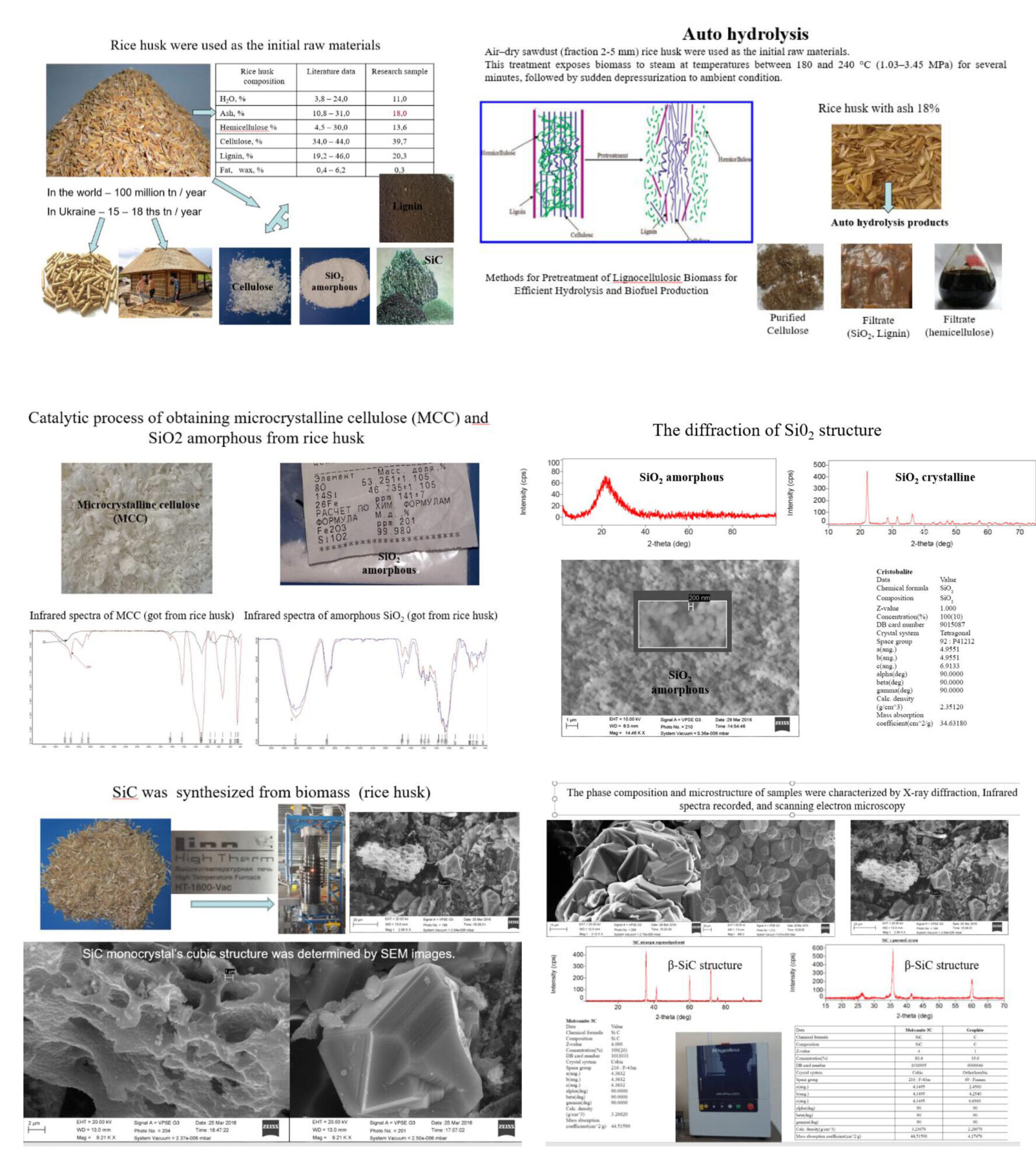

A technological solution has been developed for obtaining high-purity silicon dioxide from rice husks in an environmentally and economically safe manner. Fluoride technology was used to extract silicon dioxide. It allows used catalysts to be recycled, making it environmentally and economically efficient. The Department's researchers have demonstrated that the amorphous silica obtained with varying degrees of purity (99.0000-99.9999%) can be further transformed into silicon carbide of differing hexagonality or used as a practical component of stress-protective nanocomposite preparations for pre-sowing seed treatment and fertilisation of vegetative plants.

The current state of scientific research in the field of kinetics of chemical transformations in cascade multistage processes of deep oxidation of liquid organic substances by molecular oxygen is considered. The absence of consistent views in the scientific literature on the mechanism of influence of ultra-low doses of nanoparticles on the energy yield of energy materials during deep oxidation and combustion is noted. Laboratory samples of carbon spheroidal nanoclusters, toroidal nanoclusters of polyoxomolybdates and metal complex compounds with ligand environments of various structures have been synthesised. The influence of selected compounds on the kinetics of the initial stages of oxidation of model liquid substrates was evaluated, and the possibility of inversion of the action of such chemical additives on the oxidation of liquids at low temperatures was shown. The dependence of the antioxidant and anti-wear properties of copper chelate compounds with fluorine-containing ligands on the structure of these metal complexes was investigated and revealed. The prospect of using these metal complexes at ultra-low concentrations (10–3 % by mass) as multifunctional additives to alcohol-containing motor fuels has been demonstrated. A dual mechanism of the effect of carbon spherical nanocluster additives on the anti-wear properties of liquid hydrocarbon motor fuels has been revealed and explained. Based on the identified anomalous dependencies of the physicochemical properties of solutions on the concentrations of carbonaceous nanoparticles, views have been developed on the mechanism of action of ultra-low quantities of nanoscale additives during deep oxidation and combustion of liquid motor fuels. The idea behind the proposed mechanism is that, under the influence of impurities, the supramolecular structure formed by the initial polar oxidation products in solutions changes from a continuous network of hydrogen bonds to local domain clusters. It has been shown that such a change in the supramolecular structure in a liquid facilitates the diffusion and evaporation of fuel molecules from the liquid phase to the adjacent reaction gas region. The optimal concentration range of carbon nanoparticle additives in fuels for maximum energy efficiency and improved environmental friendliness of gasoline, diesel and jet fuel combustion has been theoretically and experimentally substantiated.

A technology for deep dewatering of wastewater sludge (using the example of the Bortnitsa aeration station BAS) using container technology (GeoTube technology elements) has been developed, and the possibilities of applying this technology in real conditions have been investigated. Its high efficiency in dewatering aerobically stabilised sludge and treating return sludge water has been demonstrated. A technological scheme of processes has been developed, the implementation of which will solve an extremely acute environmental problem in Kyiv: reduce the load on sludge sites by more complete dewatering of sludge and eliminate the potential threat of breaching barrier dams and catastrophic pollution of the Dnieper River; significantly improve the quality of sludge water returning from sludge sites to the ‘head’ of the biological treatment process.

A pilot laboratory unit has been created, on which the process of dewatering sediments of various origins has been tested in the mode ‘sediment outside the container > water through geotextile material into the container with its constant removal’. A series of experiments on sludge dewatering was conducted at this pilot setup in the aerobically stabilised sludge (ASS) workshop of the Bortnytsia aeration station. The characteristics of the water obtained in the filtration processes are given in the tables. The regeneration modes of the filter geotextile were tested, and the productivity of the pilot setup was determined.

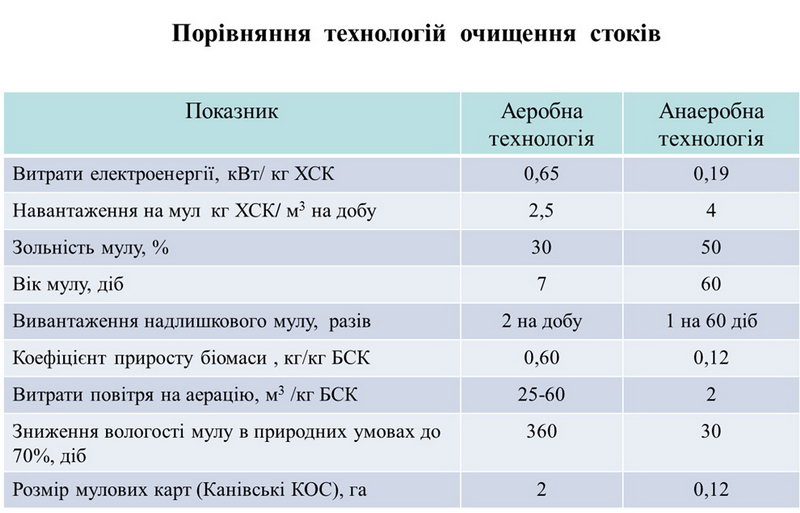

A technology has been developed for treating industrial and domestic wastewater for small towns and settlements by anaerobic digestion under psychrophilic conditions. The technology is based on the concept of modernising existing biological treatment facilities for municipal wastewater, which involves:

Treatment of municipal wastewater in psychrophilic conditions is performed by anaerobic microorganisms that biodegrade water-soluble organic compounds (pollutants). The use of such agrobiocenoses has made it possible to treat wastewater and reduce the amount of sludge and excess sludge by tens of times.

A technology has been developed for treating industrial and domestic wastewater for small towns and settlements by anaerobic digestion under psychrophilic conditions. The technology is based on the concept of modernising existing biological treatment facilities for municipal wastewater, which involves:

Treatment of municipal wastewater in psychrophilic conditions is performed by anaerobic microorganisms that biodegrade water-soluble organic compounds (pollutants). The use of such agrobiocenoses has made it possible to treat wastewater and reduce the amount of sludge and excess sludge by tens of times.

The implementation of this technology provides the following:

The technology has been implemented at the sewage treatment facilities in Kaniv, resulting in an increase in the depth of wastewater treatment and a reduction in the amount of sludge by approximately 50 times, which has reduced the area of sludge sites from 2.0 to 0.12 hectares.

Widespread implementation of this technology with minimal financial and resource costs could significantly improve the environmental situation in Ukraine.

Currently, existing technologies do not provide for their comprehensive utilisation. The Institute of Bioorganic Chemistry and Petrochemistry of the NAS of Ukraine has developed a waste-free method for processing rice husks into liquid products: cellulose, combustible gas with a calorific value of 3600–4000 kcal/kg, and silicon dioxide with a purity of 99.98%.

Laboratory equipment has been developed to study the process of explosive autohydrolysis of plant biomass in a wide range of temperatures and pressures. The research showed that all plant-based raw materials that went through the explosive autohydrolysis process had their structure broken down, and the final product mixture looked like a paste. Further processing of the obtained mixture allowed it to be separated into the following components: microcrystalline cellulose, hemicellulose, water-soluble sugars and lignin. It has been established that the preliminary treatment of vine-shaped millet under explosive autohydrolysis conditions promotes the intensification of the fermentation process (Clostridia acetobytylicum bacteria) towards the production of biobutanol, which, in our opinion, is due to the defibration of the plant material, i.e. the opening of its structure, which in turn facilitates the access of bacteria to nutrients. According to the results of the fermentation of vine millet treated under autohydrolysis conditions, the yield of butanol was 3.0 g/l. At the same time, world achievements are at the level of 2.0-2.5 g/l.

The Institute has developed a new generation of complex organo-mineral fertilisers based on sediments from the Bortnytsia aeration station and ash residues from plant waste. Field trials of these fertilisers in 2018-2019 confirmed their high agrochemical efficiency. Their use improved the nitrogen and phosphorus nutrition of the test plants, which contributed to an increase in corn yield by 5.1 tonnes per hectare, winter wheat by 2.9 tonnes per hectare and an increase in protein content by 18.5% and 16.8%, respectively, in the absence of toxic microelements. The use of such fertilisers also contributed to improving the fertility of the experimental soil.

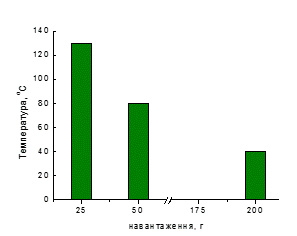

Films for use as edible packaging to protect products from mechanical damage and biological and chemical influences. They maintain optimal moisture content and protect against staling. The films contain nutrients: pectin, beta-carotene, vitamins B and U, betaine, fibre, sorbents. All samples are soluble in water at room temperature. Within 10–15 minutes, the films break down into separate particles, which then dissolve. The diagram shows the dependence of the temperature at which the deformation of the samples begins on a constant load. The strength limit is 10, 2.5 and 1.25 kg/cm2 at temperatures of 40, 80 and 130 °C, respectively.

Specialists from the V.P. Kukhar Institute of Bioorganic Chemistry and Petrochemistry of the National Academy of Sciences of Ukraine, together with the State Scientific and Production Corporation ‘Kyiv Institute of Automation’ and Scientific and Production Enterprise - LLC ‘Alfa-Stevia LTD’ have developed a highly efficient technology

for the comprehensive processing of filtrate from landfill No. 5 of the Kyiv municipal solid waste landfill. The technological scheme is fully adapted to the existing infrastructure of landfill No. 5, designed to process up to 1,000 m3 of filtrate per day and includes the following stages:

The technology can be applied to other similar facilities. The developed technology for comprehensive filtration treatment has undergone sanitary and epidemiological examination at the Marzieiev Institute for Public Health of the National Academy of Medical Sciences of Ukraine. The same institute has approved the technical and economic feasibility study developed based on the above-mentioned technology, entitled 'Implementation of the modernisation of the technological complex for the preparation, processing and disposal of filtration water at the solid waste landfill No. 5 in the village of Pidhirtsi'. As a result, a conclusion of the state sanitary and hygienic examination dated 14 August 2008, No. 05.03.02-07/52262, was obtained, according to which the specified feasibility study meets the requirements of the current sanitary legislation of Ukraine and can be used in the declared field of application (public utilities).

The most important publications of the Department researchers

Dmytro Kamenskyh

Senior Research Fellow, Candidate of Chemical Sciences, Senior Researcher

http://orcid.org/0000-0002-7341-2386

https://www.scopus.com/authid/detail.uri?authorId=36241538700

https://scholar.google.com.ua/citations?user=5c0WskQAAAAJ&hl=ru

Tetiana Tkachenko

Senior Research Fellow, Candidate of Chemical Sciences, Senior Researcher

https://orcid.org/0000-0002-1295-0084

https://www.scopus.com/authid/detail.uri?authorId=57194224516;

https://www.webofscience.com/wos/author/record/AAB-2775-2020

Volodymir Pyliavsky

Senior Research Fellow, Candidate of Chemical Sciences, Senior Research Fellow

https://scholar.google.com.ua/citations?hl=uk&hl= uk&pli=1&user=kpz2jBMAAAAJ

https://www.scopus.com/authid/detail.uri?authorId=6508367809

Maryna Aksylenko

Senior Research Fellow, Candidate of Agricultural Sciences

https://www.scopus.com/authid/detail.uri?authorId=57222660810

https://scholar.google.com.ua/citations?user=7eFn0-kAAAAJ&hl=ru

Tetiana Kameneva

Senior Research Fellow, Candidate of Chemical Sciences, Senior Research Fellow

https://orcid.org/0000-0003-3971-9808

https://scholar.google.com.ua/citations?user=dC7dukoAAAAJ&hl=uk

https://www.scopus.com/authid/detail.uri?authorId=6603961132

Nataliia Himach

Research Fellow, Candidate of Chemical Sciences

https://orcid.org/0000-0002-3383-1439https://www.scopus.com/authid/detail.uri?authorId=57212500478

https://scholar.google.com.ua/citations?user=4HZOnMMAAAAJ&hl=ru

Olga Haidai

Research Fellow, Candidate of Chemical Sciences

https://orcid.org/0000-0003-2710-2560

https://www.scopus.com/authid/detail.uri?authorId=57574036200

https://scholar.google.com.ua/citations?user=6cztDZAAAAAJ&hl=ru

Oleksandr Pavliuk

Junior Research Fellow, Candidate of Chemical Sciences

https://orcid.org/0000-0002-0857-4979

https://www.scopus.com/authid/detailuri?authorId=57212587846

https://scholar.google.com.ua/citations?user=YiUkgE4AAAAJ&hl=ru

Bohdan Korinenko

Junior Research Fellow, PhD

https://orcid.org/0009-0001-7581-5656

https://scholar.google.com/citations?user=6hkOjzUAAAAJ&hl=uk

Viktor Burdeinyi

1 Category Engineer

https://orcid.org/0009-0001-5464-9636

https://scholar.google.com/citations?hl=ru&user=i7yze-gAAAAJ

https://www.scopus.com/authid/detail.uri?authorId=59418900700

Mariia Baran

1 Category Engineer

https://orcid.org/0000-0002-3234-7661

https://www.scopus.com/authid/detail.uri?authorId=57792048200

https://scholar.google.com/citations?user=KyI3r4MAAAAJ&hl=uk

Serhii Doroshenko

1 Category Engineer

Tamara Reshetar

1 Category Engineer

Mykhailo Kalashnikov

1 Category Engineer

Liudmyla Starzhynska

2 Category Engineer

Liliia Barybina

Technician

https://www.scopus.com/authid/detail.uri?authorId=59480003500

Denys Kotvytskyi

Technician

Andrii Vynohradov

Technician

Joint research activities of the Department with Namik Kemal University (Turkey) and Baku State University in the field of obtaining high-purity nanoscale materials, modification of the obtained substances with organic and composite materials, followed by studying their characteristics. Research services ‘Experimental studies of the parameters and composition of lignocellulosic feedstocks, in particular, determination of the content of main biopolymers (cellulose, hemicellulose, lignin), ash and other components and parameters’ commissioned by the National University of Life and Environmental Sciences of Ukraine.

V.P. Kukhar Institute

of Bioorganic Chemistry and Petrochemistry

NAS of Ukraine

© 2026 IBOPC NAS of Ukraine