Запропоновано спосіб гомогенно-каталітичної етанольної переестерифікації рослинних олій (повністю біовідновлювальної і продукованої в Україні сировини) та розроблено оригінальну технологію одержання етилових естерів жирних кислот, що можуть бути використані в ролі альтернативного моторного палива біологічного походження для дизельних двигунів (біодизельного палива). Перевагою даної технології над класичною є заміна високотоксичного метилового спирту, який одержується з природного газу, на екологічно-безпечний біоетанол, що робить сировинну базу цього процесу повністю біологічно відновлювальною, а синтезоване етанольне біодизельне паливо – екологічно безпечнішим.

Запропоновано спосіб гомогенно-каталітичної етанольної переестерифікації рослинних олій (повністю біовідновлювальної і продукованої в Україні сировини) та розроблено оригінальну технологію одержання етилових естерів жирних кислот, що можуть бути використані в ролі альтернативного моторного палива біологічного походження для дизельних двигунів (біодизельного палива). Перевагою даної технології над класичною є заміна високотоксичного метилового спирту, який одержується з природного газу, на екологічно-безпечний біоетанол, що робить сировинну базу цього процесу повністю біологічно відновлювальною, а синтезоване етанольне біодизельне паливо – екологічно безпечнішим.

Синтезоване за розробленою технологією на укрупненій дослідній установці ІБОНХ НАН України біодизельне паливо показало унікальні енергоекологічні характеристики: у сумішах з дизельним паливом нафтового походження в концентраціях 20-80 % синтезований продукт переважає нафтове дизпаливо підвищеної якості (Євро) марки С виду ІІ дещо (до 1 %) більшими значеннями максимальної потужності двигуна, на 2-7 % більшими величинами максимального крутного моменту, на 1-3 % вищими коефіцієнтами корисної дії двигуна, характеризується на 1-5 % меншими значеннями викидів в атмосферу діоксиду вуглецю, меншими в 1,3-1,5 рази значеннями викидів оксидів азоту, в 1,2-1,3 рази - оксиду вуглецю, в 1,9-3,3 разів - продуктів неповного згоряння, в 1,1-2 рази нижчою димністю, причому останні чотири характеристики поширюються на весь діапазон концентрацій, і на чисте біодизельне паливо включно.

Синтезований продукт за моторно-екологічними показниками роботи двигуна перевершує паливо на метанольній основі і є єдиним з відомих на сьогодні біодизельних палив, у результаті спалювання яких у циліндрах двигунів внутрішнього згоряння вміст оксидів азоту не зростає, а, навпаки, суттєво зменшується, що робить його екологічно повністю прийнятним.

На сьогодні аналогів біодизельного палива етанольної переестерифікації олій, як і технології його одержання, в Україні не існує.

Керівник розробки: д.х.н. Патриляк Любов Казимирівна, тел. (044) 559-71-60.

В Інституті розроблено ефективні екологічно безпечні регулятори росту рослин (Івін, Потейтін, Емістим-С, Агростимулін, Бетастимулін, Зеастимулін, Чаркор, Трептолем), які підвищують на 15-20% врожайність основних сільськогосподарських культур; поліпшують якість продукції рослинництва; підвищують стійкість рослин до хвороб, шкідників та стресових факторів; при спільному використанні з пестицидами дозволяють на 25-30% зменшити дози пестицидів, а відтак – зменшити пестицидне навантаження на грунти; є низьковитратними препаратами (10-15 мл для обробки 1 т насіння, або 5-10 мл для оприскування 1 га посівів); забезпечують високу рентабельність (1 гривня, витрачена на застосування регуляторів росту рослин, може давати додаткову продукцію на 15-20 гривень). На зазначені регулятори росту рослин Інститут біоорганічної хімії та нафтохімії ім. В.П. Кухаря НАН України розробив та зареєстрував Технічні Умови України для застосування їх при вирощуванні основних сільськогосподарських культур в Україні, за якими Товариство з обмеженою відповідальністю "Високий врожай" і Державне підприємство “Міжвідомчий науково-технологічний центр «Агробіотех» на підставі наданих Інститутом ліцензій виготовляє та реалізує регулятори росту рослин.

Застосовується при вирощуванні зернових, зернобобових, технічних, кормових, овочевих, плодово-ягідних культур, в лісовому господарстві, ландшафтному дизайні, на квітах та газонах.

Вплив на рослини:

Збільшує енергію проростання і польову схожість насіння, сприяє розвиту кореневої системи, підвищує стійкість рослин до хвороб та стресових факторів, знімає фітотоксичний ефект, має антимутагенну дію, підвищує врожай та якість вирощеної продукції.

Застосовується в технологіях вирощування овочевих культур-огірків, томатів, перцю, капусти, моркви, баклажанів; технічних культур – тютюну, бавовнику, ефіроолійних сортів троянд; кімнатних рослин. Особливо ефективний при обробці насіння.

Вплив на рослини:

Зменшує захворювання рослин, знижує в плодах вміст нітратів, важких металів, радіонуклідів. Забезпечує прибавки врожаю: огірків – 25-70 ц/га; томатів – 35-80 ц/га; (в закритому ґрунті, відповідно, 1,5-4,5 кг/м2 і 1,7-5,0 кг/м2); капусти – 30-50 ц/га; перцю солодкого – 20-40 ц/га. Прискорює дозрівання та збільшує вихід раннього врожаю на 20-30%.

Застосовується в технології вирощування картоплі для обробки бульб та обприскування плантацій.

Вплив на рослини:

Стимулює ріст і розвиток картоплі у початковий період, підвищує стійкість до захворювань. Загрублює листя і стебла, утруднюючи їх пошкодження колорадським жуком. Підвищує врожай на 30-80 ц/га, збільшує масу бульб і вміст у них крохмалю та вітамінів.

Препарат з широким спектром дії. Застосовується для обробки насіння і обприскування посівів пшениці, ячменю, сої, гречки, гороху, льону, конюшини, люцерни, сорго.

Вплив на рослини:

Препарат вільно проходить через мембрани клітин, активізує процеси обміну і прискорює поділ клітин. Внаслідок чого швидко наростає потужна коренева система та розвинена листова поверхня, інтенсифікується синтез хлорофілу. Агростимулін зменшує токсичну дію пестицидів на культурні рослини, має анти мутагенний ефект. На 10-20% збільшує врожай та поліпшує якість вирощеної продукції.

Застосовується в технологіях вирощування цукрових, кормових та столових буряків для обробки насіння та обприскування посівів.

Вплив на рослини:

Підвищує польову схожість насіння, інтенсифікує розвиток кореневої системи і гички, активізує утворення хлорофілу, підвищує стійкість до хвороб та стресів. Препарат активно впливає на ферментні системи, відповідальні за ріст коренеплоду та накопичення цукрів, стимулюючи відтік поживних речовин до коренеплодів. Збільшує врожай коренеплодів на 25-60 ц/га одночасно з підвищенням цукристості на 0,5-1,2%.

Застосовується в технологіях вирощування кукурудзи на зерно і зелену масу для оброки насіння і обприскування посівів.

Вплив на рослини:

Зменшує строки проростання насіння, прискорює розвиток молодих рослин, підсилює стійкість до хвороб, активізує фотосинтез, знижує фітотоксичну дію пестицидів, має анти мутагенний ефект. Зеастимулін підвищує врожай зерна кукурудзи на 7-10 ц/га, зеленої маси на 50-70 ц/га, на 2-5% збільшує вміст жирів і протеїнів у зерні.

Укорінення зелених і задерев’янілих живців рослин, обробка коріння розсади і саджанців перед висадкою в ґрунт, підживлення кореневої системи дерев та кущів.

Вплив на рослини:

Сприяє підвищенню кількості первинних корінців, їх інтенсивному росту і розвитку, збільшує довжину прирост у та прискорює його визрівання. Істотно підвищує рентабельність процесу вегетативного розмноження рослин.

Застосовується в технологіях вирощування соняшника та ріпаку для обробки насіння та обприскування посівів

Вплив на рослини:

Препарат сприяє формуванню потужної кореневої системи та листової поверхні, зменшує захворюваність рослин та підвищує їх стійкість до стресогенних факторів. Збільшує діаметр кошиків соняшника на 4-5 см. Підвищує врожайність насіння на 2,5-4,0 ц/га і вміст в ньому олії на 1,5-2,5%.

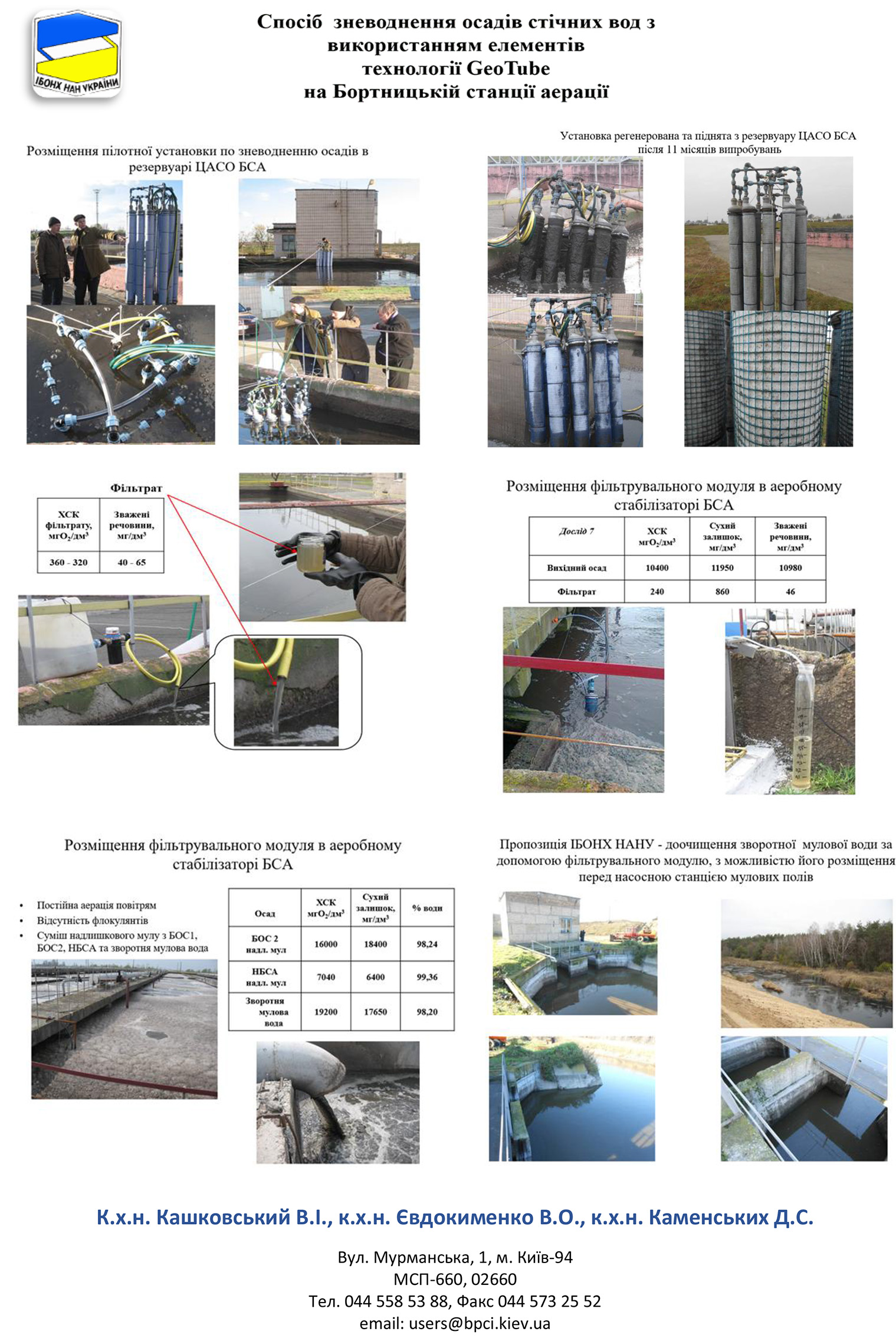

Розроблено технологію глибокого зневоднення осадів стічних вод (на прикладі Бортницької станції аерації БСА) за допомогою контейнерної технології (елементів технології GeoTube) та досліджено можливості застосування такої технології в реальних умовах. Показана її висока ефективність при зневодненні аеробно-стабілізованих осадів та очищенні зворотної надмулової води. Розроблено технологічну схему процесів, впровадження яких дозволить вирішити вкрай гостру екологічну проблему Києва: зменшити навантаження на мулові майданчики за рахунок більш повного зневоднення мулів і ліквідувати потенційну загрозу прориву загороджувальних дамб та катастрофічного забруднення Дніпра; суттєво покращити якість надмулової води, що повертається з мулових майданчиків у „голову” процесу біологічного очищення.

Створено пілотну лабораторну установку, на якій відпрацьовано процес зневоднення різних за природою осадів в режимі «осад зовні контейнера > вода через геотекстильний матеріал всередину контейнера з постійним її відведенням». На даній пілотній установці проведено серію дослідів по зневодненню осадів у цеху аеробно-стабілізованих осадів (ЦАСО) Бортницької станції аерації. Характеристики одержаної води у процесів фільтрування наведено у таблицях. Відпрацьовано режими регенерації фільтрувальної геотканини та визначено продуктивність пілотної установки.

Докладніше на постері:

Розроблено технологію очищення промислово-побутових

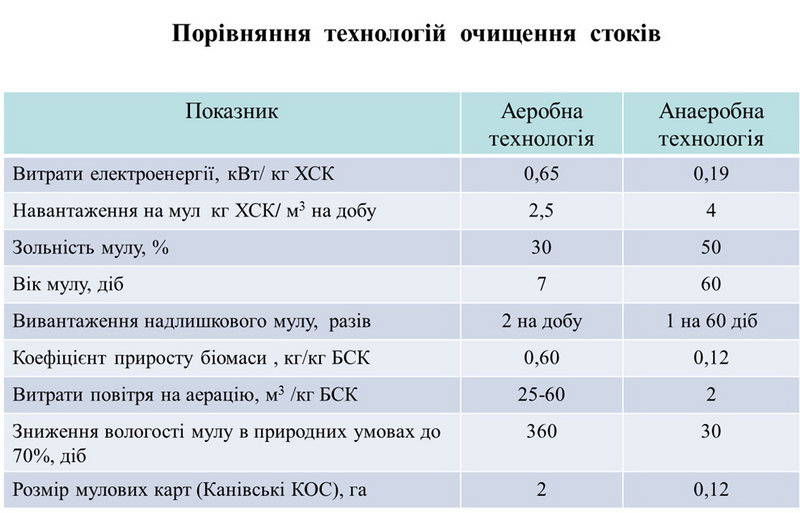

стічних вод для малих міст і населених пунктів шляхом анаеробного зброджування в психрофільних умовах. Технологія основана на концепції модернізації існуючих очисних споруд біологічного очищення комунальних стічних вод, яка передбачає:

Очистка комунальних стоків в психрофільних умовах здійснюється анаеробними мікроорганізмами, які проводять біодеградацію розчинних у воді органічних сполук (полюантів). Застосування таких агробіоценозів дозволило провести очистку стоків та зменшити кількість осадів та надлишкових мулів в десятки разів.

Втілення цієї технології забезпечує наступне:

Технологію впроваджено на каналізаційно-очисних спорудах м. Канева, наслідком чого стало збільшення глибини очищення стічних вод і зменшення кількості осадів (мулу) приблизно в 50 раз, що дозволило зменшити площу мулових майданчиків з 2,0 до 0,12 га.

Широке впровадження згаданої технології при мінімальних фінансових і ресурсних затратах може істотно поліпшити екологічну ситуацію в Україні.

Розроблено гнучку технологічну схему безвідходної переробки органовмісних відходів, включаючи осади комунальних стічних вод, з одержанням ліквідних продуктів.

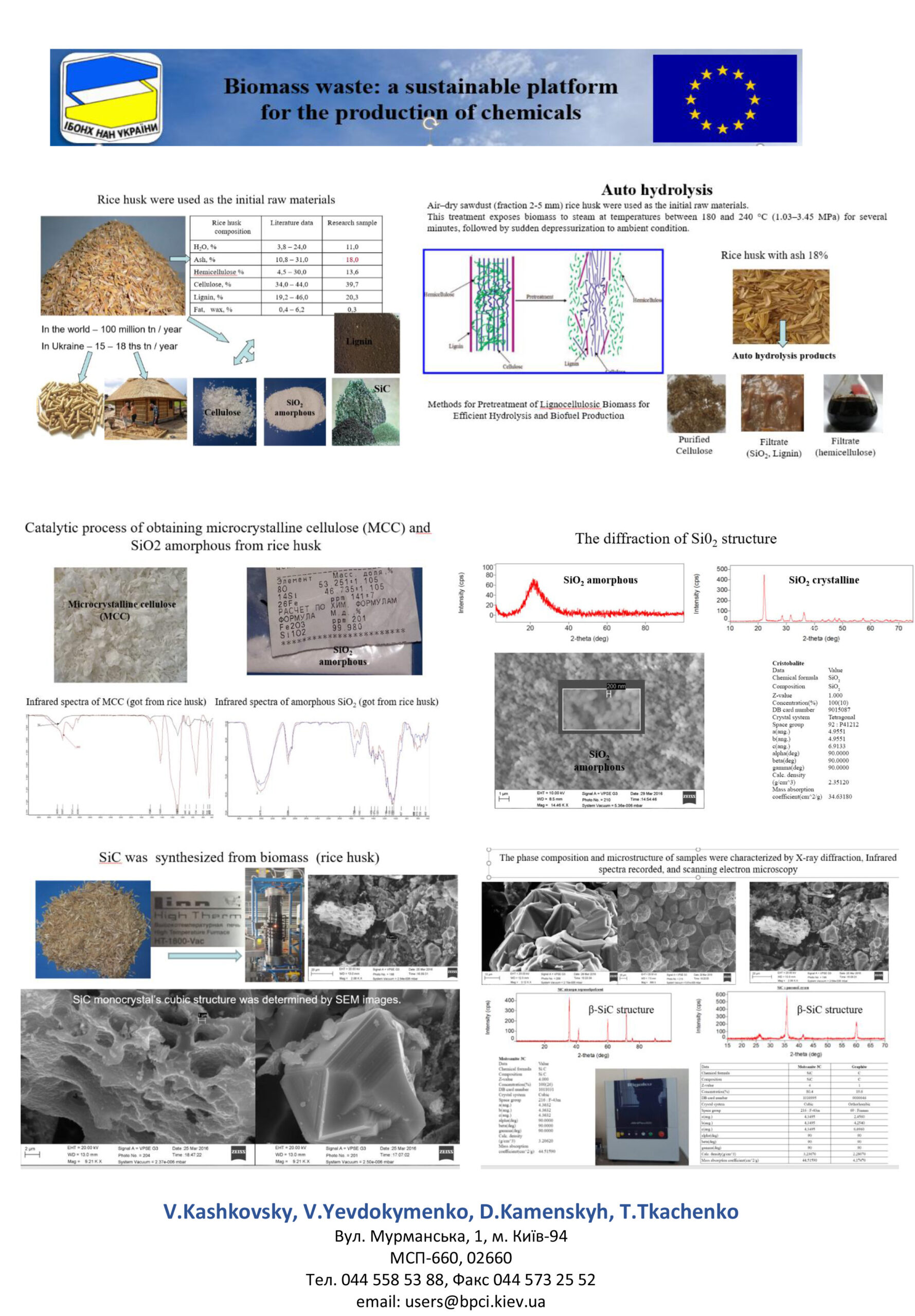

Рисова лузга відноситься до багатотоннажних техногенних відходів. На сьогодні існуючі технології не забезпечують їх комплексну утилізацію. В Інституті біоорганічної хімії та нафтохімії Національної академії наук України розроблено безвідходний спосіб переробки рисової лузги у ліквідні продукти: целюлозу, горючий газ із теплотворною здатністю 3600–4000 ккал/кг, діоксид кремнію чистотою 99,98%.

Докладніше на постері:

(044) 559-20-71, (044) 559-70-54.

Розроблено технологію одержання високочистого аморфного

діоксиду кремнію із кремнієвмісних відходів техногенного походження, який включає стадії: підготовки сировини та її змішування з фторуючим агенту; нагріву суміші до заданої температури; сублімації утвореного гексафторсилікату амонію; його гідроліз в лужному середовищі; фільтрації і сушки діоксиду кремнію; регенерації вихідного фторуючого агенту і аміачного розчину.

Переробку утвореного після одержання діоксиду кремнію залишку у напрямку вилучення з нього інших оксидів або шляхом використання такого залишку при будівництві доріг, плануванні промислових майданчиків, створенні матеріалів різного призначення.

Спосіб відпрацьовано на різній кремнієвмісній сировині. Аморфний кремнезем високої чистоти одержано із золи Трипільської ТЕС, зольних залишків після спалювання осадів Бортницької станції аерації і Калитнянського свинокомплексу, а також піску кар’єрного і кварцового. Відпрацьовано всі технологічні параметру процесу та підібрано необхідне обладнання. Створено технологічну схему дослідно-промислового та промислового виробництва аморфного діоксиду кремнію.

Створено лабораторне обладнання для дослідження процесу вибухового автогідролізу рослинної біомаси в широкому діапазоні температур і тисків. Проведені дослідження показали, що всі вихідні матеріали рослинного походження, які були оброблені в умовах процесу вибухового автогідролізу, зазнали розволокнення своєї структури, а суміш кінцевих продуктів мала кашоподібний вигляд. Подальша обробка отриманої суміші дозволила розділити її на такі складові: мікрокристалічну целюлозу, геміцелюлозу, водорозчинні цукри та лігнін. Встановлено, що попередня обробка лозовидного проса в умовах вибухового автогідролізу сприяє інтенсифікації процесу ферментації (бактерія Clostridia acetobytylicum) у напрямку одержання біобутанолу, що обумовлено, на наш погляд, розволокненням рослинного матеріалу, тобто розкриттям його структури, що в свою чергу, полегшує доступ бактерій до поживних речовин. За результатами ферментації лозовидного проса, обробленого в умовах автогідролізу, вихід бутанолу становив 3,0 г/л. У той же час світові досягнення знаходяться на рівні 2,0-2,5 г/л.

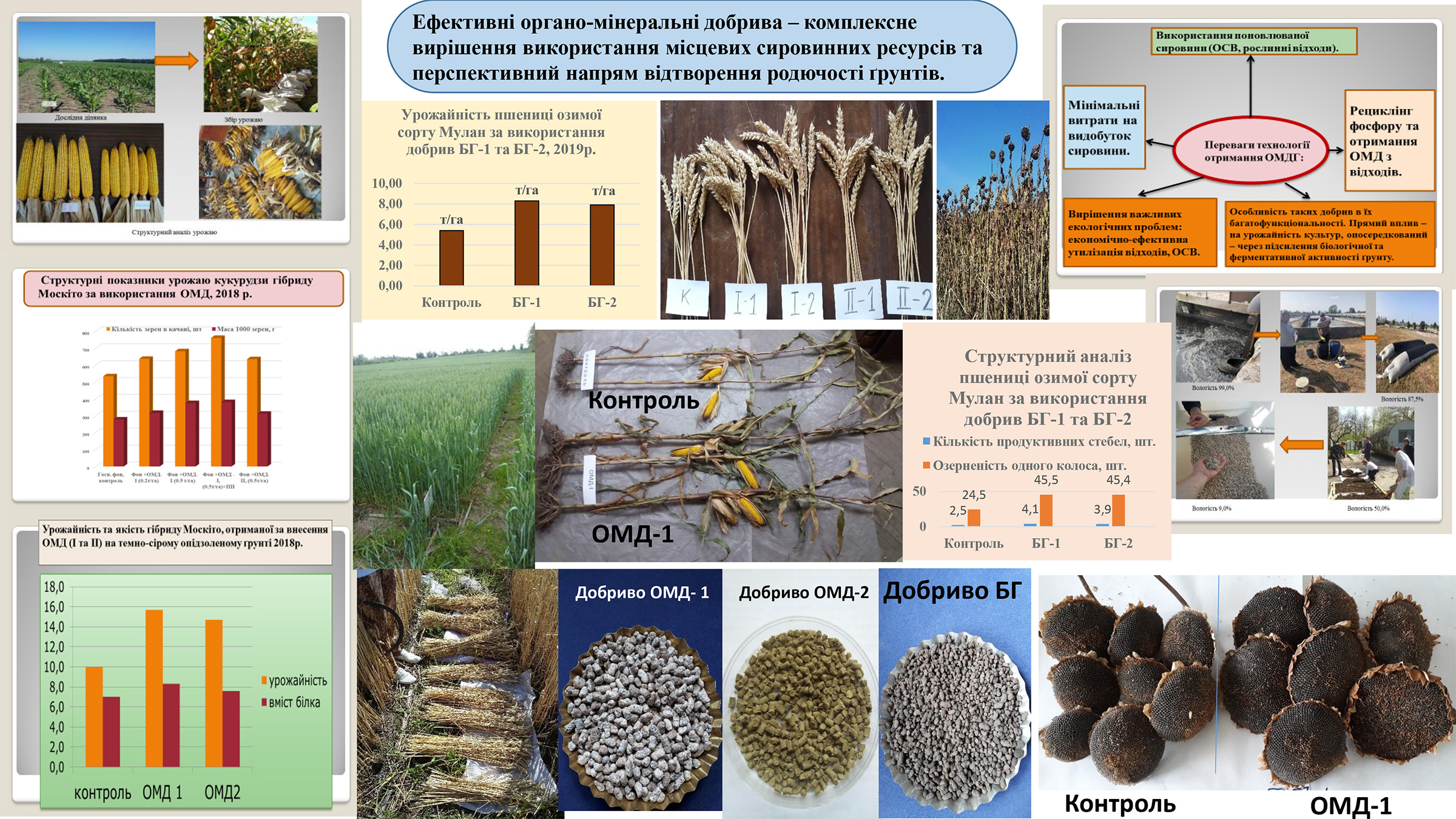

В Інституті розроблені комплексні органо-мінеральні добрива нового покоління на основі осадів Бортницької станції аерації та золових залишків рослинних відходів. Польові випробування зазначених добрив в 2018-2019 рр. підтвердили їх високу агрохімічну ефективність. За їх використання відбувалось покращення азотно-фосфорного живлення дослідних рослин, що сприяло підвищенню врожайності кукурудзи на 5,1 тонни з 1 гектару, пшениці озимої - на 2,9 тонни з 1 гектару та підвищення вмісту білку на 18,5% і 16,8% відповідно, за відсутності вмісту токсичних мікроелементів. Використання таких добрив також сприяло покращенню показників родючості дослідного темно-сірого опідзоленого ґрунту.

Плівки для застосування як їстівна упаковка для захисту продуктів від механічних ушкоджень, біологічного та хімічного впливу.

Зберігають оптимальну вологість та захищають від черствіння.

Плівки містять поживні речовини: пектин, бета-каротин, вітаміни групи В та U, бетаїн, клітковину, сорбенти. Всі зразки розчинні у воді при кімнатній температурі.

За 10 - 15 хв плівки розкладаються на окремі частинки, які потім розчиняються.

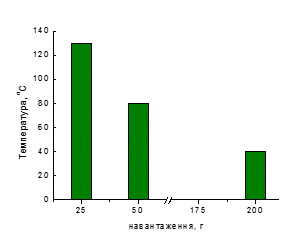

На діаграмі наведено залежність температури початку деформації зразків від постійного навантаження. Межа міцності при цьому складає 10, 2.5 та 1,25 кг/см2 при температурах відповідно 40, 80 та 130°С.

Спеціалістами Інституту біоорганічної хімії та нафтохімії НАН України разом із Державною науково-виробничою корпорацією “Київський Інститут автоматики” та НВП “Альфа Стевія” розроблено високоефективну технологію комплексної переробки фільтрату полігону № 5 київського міського звалища ТПВ. Технологічна схема повністю адаптована до існуючої інфраструктури полігону № 5, розрахована на переробку до 1000 м3 фільтрату щодобово і передбачає наступні стадії:

Технологія може бути застосована на інших подібних об’єктах. Розроблена технологія комплексної переробки фільтрату пройшла санітарно-епідеміологічну експертизу в Інституті гігієни та медичної екології ім. О.М. Мазаєва АМН України, цим же Інститутом погоджене розроблене на основі вищезгаданої технології техніко-економічне обґрунтування “Впровадження модернізації технологічного комплексу підготовки, переробки та знешкодження фільтраційних вод полігону ТПВ № 5 в с. Підгірці”. Як результат – одержано Висновок державної санітарно-гігієнічної експертизи від 14.08.2008 р. за № 05.03.02-07/52262 згідно якого означене ТЕО відповідає вимогам діючого санітарного законодавства України і може бути використано в заявленій сфері (комунальне господарство) застосування.

Процес ущільнення сміття і утворення внаслідок розкладу органічних сполук так званого фільтрату, який містить велику кількість токсичних речовин.

На полігоні №5 (с. Підгірці) об’єм фільтрату перевищує 500 тис. м3.

Накопичування утворюваного токсичного фільтрату і попадання його в грунтові води може стати причиною екологічної катастрофи.

Розроблена технологія передбачає повну очистку фільтрату, яка включає стадії реагентно-окислювальної очистки фільтрату, його доочистки системою зворотнього осмосу та скид води через біоплато в навколишнє середовище і вирішує проблему утвореного в процесі очистки концентрованого осаду.

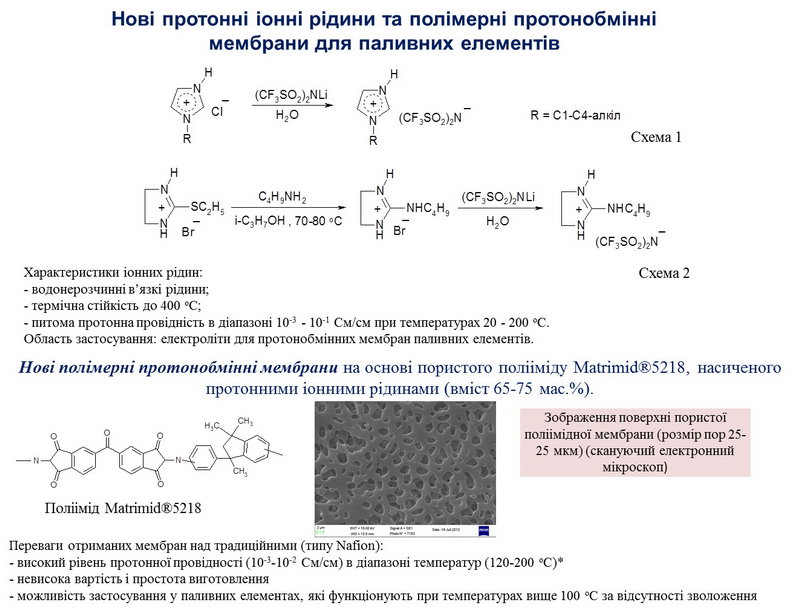

Розроблено водонерозчинні протонні йонні рідини, які включають катіони 1-алкілімідазолію, 2-алкіламіноімідазолінію, N-бутилгуанідинію і аніон біс(трифторметил-сульфоніл)імід. Встановлено, що такі сполуки термічно стійкі до 370-400°С і мають високу питому йонну провідність, яка досягає 10-2 См/см при температурі 180°С.

Отримані йонні рідини є перспективними електролітами для застосування в безводних протонпровідних системах, зокрема в полімер-електролітних мембранах для паливних елементів.

Керівник розробки: Рогальський Сергій Петрович, тел.: (044) 559-46-22.

На основі курячого жиру розроблено низку функціональних екобезпечних ПАР, біопалив і мастильних матеріалів. Добрі змащувальні властивості забезпечують технологічним рідинам, з їх використанням, високі триботехнічні характеристики, хороші миючі й охолоджуючі властивості, що дозволяє рекомендувати їх не лише як біопалива, а й функціональні додатки до технологічних систем для різноманітних сфер з підвищеними токсиколого-гігієнічними і екологічними вимогами. Літійове пластичне мастило на базі курячого жиру, як загусника, за показниками пенетрації, температури крапання, механічної стабільності та інших вимог технічних умов не поступається товарному мастилу Літол-24 (ГОСТ 21150), комплексне кальційове – мастилу Уніол-2М/1 (ГОСТ 1033, ТУ 38.5901243), гідратоване кальційове – мастилу «Солідол жировий» (ГОСТ 1033). Водночас за біорозщеплюваністю нові мастила на 10-20 % переважають існуючі товарні аналоги, що відкриває шлях до здешевлення і подальшої екологізації технології виробництва і використання мастильних матеріалів.

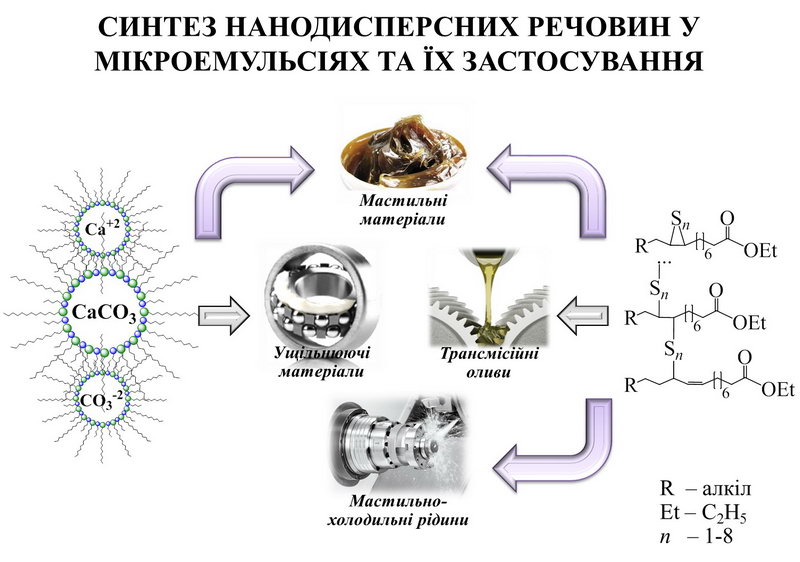

З використанням сульфурвмісних етилових естерів ВЖК олій розроблено композиції мастильно-холодильних рідин мікроемульсійного типу, що відрізняються термодинамічною, седиментаційною і термічною стікістю, а також трансмісійні оливи й протизадирні мастила породоруйнівного інструменту, які за трибологічними, антиокснювальними і захисними характеристиками не поступаються, а за органолептичними, токсикологічними і екологічними характеристиками (біорозкладуваність впродовж 21 доби складає 93%) суттєво перевершують промислові аналоги. Розроблені оливи, пластичні мастила і мастильно-холодильні рідини відповідають кращим світовим аналогам. Їх практична значимість підтверджена патентами і заявками на винаходи.

Традиційні мастильні матеріали - біологічно важко розкладувані продукти (10-30 %). Виробництво їх супроводжується викидами в атмосферу понад 13 т СO2, а в процесі використання близько 36 % їх відкладається у вигляді токсичного оливного туману на грунтах і дорогах. У відділі ПАР ІБОНХ НАН України запропоновано комплексне розв’язання проблеми шляхом трансформації побічних продуктів від очистки олій з отриманням екобезпечних поліфункціональних поверхнево-активних присадок до мастильних матеріалів.

Актуальність проблеми. Сьогодні у всіх економічно розвинутих країнах Західної Європи, США і Канади в парках, міських і приміських зонах відпочинку, сільському, лісовому та водному господарствах законодавчо заборонено використання мастильних матеріалів нафтового походження, які через високу стійкість і сповільнений розклад тривалий час утримуються на поверхні землі і водойм. Замість них повсюдно використовуються екологічно чисті мастильні матеріали на основі рослинних олій, які в природі швидко і повністю засвоюються мікроорганізмами.

В ІБОНХ НАН України проведено маркетинг і визначені прогнозні показники з виробництва і застосування біопалив та мастильних матеріалів з відтворюваної рослинної сировини. На базі ріпакової й соняшникової олій, додаванням детергентно-диспергувальних додатків, розроблена аналогічна зарубіжним екологічно безпечна олива 10М-БІО, яка, за результатами випробувань на підприємствах м.Києва, відповідає світовим стандартам на оливи для двотактних бензинових двигунів.

Олива моторна 10м-Біо характеризується покращеними в’язкісно-температурними властивостями (за ТУ У 23.2-30084964-005-2003 - в’язкість кінематична при 100°С – 8,0-11,0 мм2/с (сСт); температура спалаху – понад 200°С) і за базовими показниками відповідає вимогам провідних виробників малогабаритної техніки Husquarna, Dolmar, Stihl. Вона забезпечує високу чистоту двигуна, хороші пускові якості при холодному і гарячому старті, бездоганний стан поршневих кілець і захист від зношування та корозії, високу екологічність (біорозкладність за СЕС-L-33-Т-82 складає понад 95%).

Олива моторна 10м-Біо призначена для використання у двотактних двигунах з водяним чи повітряним охолодженням шляхом попереднього змішування оливи з паливом чи роздільним автоматичним вприскуванням їх в камеру згорання.

Рекомендується для моторолерів, мопедів, мотоциклів, моторних човнів, ланцюгових пил, снігоходів, снігоприбиральних машин, газонокосарок, ножниць для підстригання живоплоту тощо.

Завдяки високим антикорозійним властивостям олива може використовуватись також для внутрішньої консервації двотактних двигунів на період зберігання, транспортування і сезонного виведення технічних засобів з експлуатації.

Олива моторна 10м-Біо змішується з різними типами палив і рекомендується до використання в двотактних бензинових двигунах з урахуванням пропозицій виробника технічних засобів, переважно при співвідношенні “олива:бензин=1:50”.

Вартість оливи 10м-Біо, завдяки використанню власної природної відновлювальної сировини, в 2-4 рази менша за аналогічного типу імпортні оливи, що закуповуються в Швеції чи Німеччині.

Олива моторна 10м-Біо може поставлятися в євробочках місткістю 216,5 л і в поліетиленових каністрах об’ємом 5 л і 1 л. Потенційний виробник – Івано-Франківська фірма “Барва”.

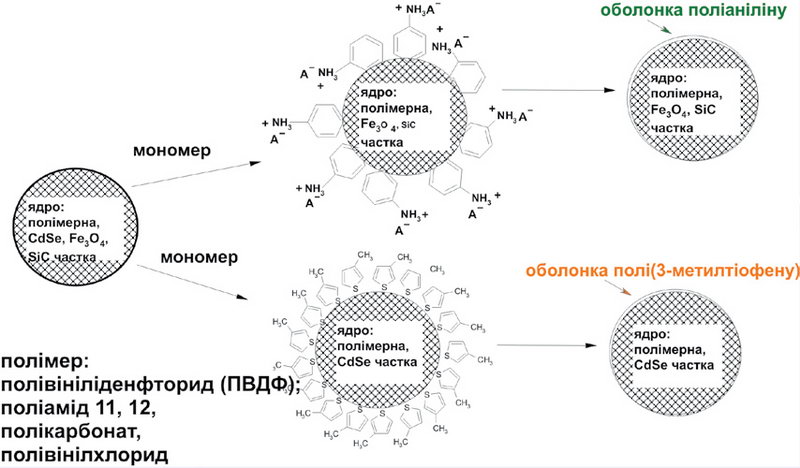

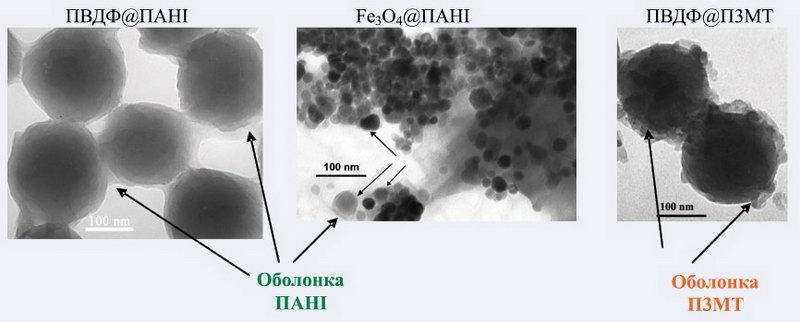

Розроблено нові способи синтезу гібридних напівпровідникових та магнітних наноматеріалів типу полімерне або неорганічне ядро-оболонка з напівпровідникового полімеру поліаніліну (ПАНІ) або полі(3-метилтіофену) (П3МТ). Способи засновані на потенціометричному контролі in situ полімеризаційного процесу, що дозволяє відслідковувати його стадії та управляти їх перебігом.

Схема синтезу:

Приклади сформованих часток гібридних композитів (електронно-мікроскопічні знімки):

Можливі застосування матеріалів: медична діагностика та лікування; сенсорика, гібридні фотовольтаїчні елементи; електромагнітний, антистатичний та антикорозійний захист тощо.

Керівник розробки: д.х.н., проф. Пуд Олександр Аркадійович,

тел.: (044) 559-70-03.

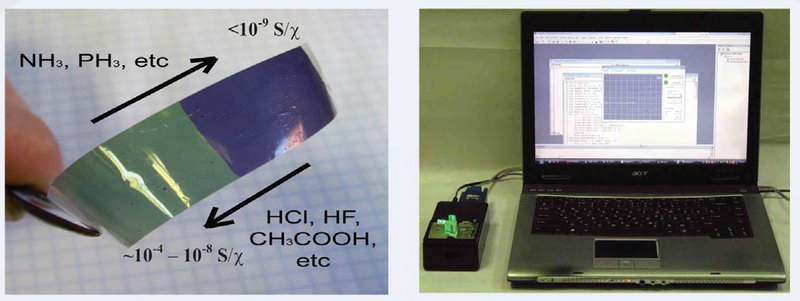

Матеріал являє собою прозору композитну полімерну плівку на основі діелектричного промислового полімеру (поліетилентерефталату, поліаміду, полікарбонату, полівініліденфториду тощо), в поверхневому шарі (1-2 мкм) якої розподілено полімеризаційним шляхом сенсорний полімер поліанілін (ПАНІ). В залежності від хімічного стану поліаніліну (емеральдинова основа або сіль), матеріал може взаємодіяти з речовинами з кислотними властивостями (пари або розчини соляної, оцтової, мурашиної кислот тощо), або з основними властивостями (аміак, розчини лугів тощо). В результаті таких взаємодій ПАНІ змінює колір, оптичну густину і електропровідність (рис. 1) і це дозволяє використовувати його композити у відповідних сенсорних пристроях. Діелектрична матриця композиту забезпечує високу міцність та стабільність сенсорного матеріалу.

Для реєстрації сенсорного відгуку розроблених матеріалів у газовій фазі по зміні їх оптичної густини розроблено сенсорну систему (рис.2). При використані ПАНІ в основній формі система дає лінійний відгук на сполуки з кислотними властивостями (напр., на мурашину кислоту 150-500 ррм), в сольовій – на сполуки з основними властивостями (напр., на аміак 4-600 ррм). Розроблені матеріал і система можуть бути використані на хімічних виробництвах, де використовується аміак або різні кислоти, для пошуку витоків цих речовин у навколишнє середовище.

Керівник розробки: д.х.н., проф. Пуд Олександр Аркадійович, тел.: (044) 559-70-03.

Розроблено каталітично-адсорбційний спосіб знесірчення (десульфурізації), що дозволяє досягти ефективного видалення з рідких вуглеводневих палив нафтового походження сірковмісних сполук, в т. ч. тіофену, бензтіофену та їх похідних.

На відміну від відомих способів десульфуризації запропонований метод забезпечує:

В процесі адсорбційно-каталітичної десульфуризації відбувається каталітичне окислення доступними окислювачами сірковмісних сполук, що забруднюють нафтопродукти, до полярних сполук, які видаляються шляхом адсорбції. Процес може бути реалізований як в ємностях з нафтопродуктами, так і в проточному чи проточно-циркуляційному реакторі з нерухомим або псевдозрідженим шаром адсорбенту-каталізатора.

Керівник розробки: к.х.н. Кашковський Володимир Ілліч,

тел.: (044) 559-20-71, (044) 559-70-54.

Призначення: Технологія призначена для покращення екологічних показників та підвищення ресурсу автомобільних двигунів без виводу автомобілів з експлуатації.

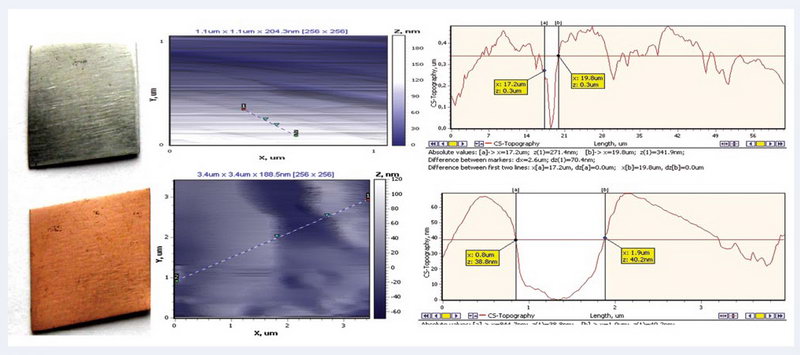

Опис розробки: Технологія полягає у періодичному відновленні зношених робочих поверхонь циліндрів двигунів без демонтажу напилюванням протизношувального металокластерного покриття через свічкові або форсуночні отвори. При обробці двигунів за цією технологією очищується камера згоряння від нагарів, відновлюється геометрія циліндрів та «заліковуються» подряпини на робочих поверхнях циліндрів, підвищується на 10-30 % компресія та вирівнюються ії значення по циліндрах, збільшується потужність двигуна, зменшуються димність і токсичність відпрацьованих газів. При багаторазовій обробці двигунів з інтервалом 40-50 тис.км пробігу ресурс експлуатації двигунів у паспортному режимі підвищується у 2-3 рази.

Зовнішній вигляд та результати атомно-силової мікроскопії покриття

Керівник розробки: к.т.н. Пилявський Володимир Степанович, тел. (044) 559-71-81.

Призначення: технологія твердих змащувальних покриттів призначена для забезпечення роботоздатності деталей у вузлах сухого тертя без застосування рідких або пластичних змащувальних композицій.

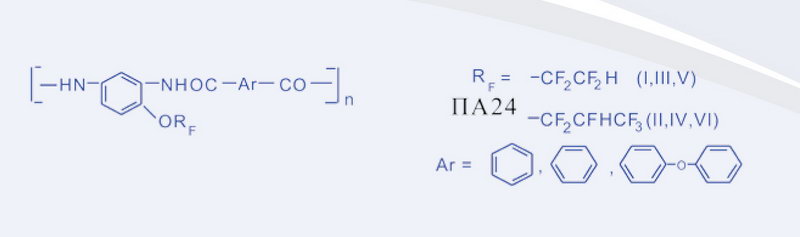

Опис розробки: Тверде змащувальне покриття (ТЗП) виготовляється у вигляді суспензії, яка складається із фторованого поліаміду (ПА-24), органічного антифрикційного наповнювача та добавок (антиоксиданти, трібополімерутворюючі компоненти).

Товщина покритя становить 0.15 - 025 мм.

Термообробка для твердіння здійснюється при 190°С протягом 2 годин, або при 80°С у присутності каталізатора.

Порівняння з аналогами: ТЗП Металофторопласт

Запропоновані ТЗП вперше були застосовані у авіації у вузлах керування предкрилками літака АН-70, а також у робототехніці на внутрішній поверхні пневмоциліндра технічного робота (cумарна наробка пневмоциліндра становила 1 000 000 циклів).

Керівник розробки: к.х.н. Шелудько Євген Валентинович тел.: (044) 559-71-81.

Високоефективний цеолітний каталізатор та екологічно чисті процеси алкілування ізобутану бутенами для одержання високооктанового компоненту бензину – алкілату, а також алкілування бензолу та толуолу олефінами С20-С24 з метою одержання алкілбензолів для виробництва алкілсульфонатних присадок нафтових змащувальних олив. Пропонований каталізатор та розроблені процеси покликані замінити екологічно ущербні процеси алкілування з використанням висококонцентрованих сірчаної та фтористоводневої кислот і хлориду алюмінію як каталізаторів.

Розроблений каталізатор характеризується підвищеними (на 1-3 %) в порівнянні з імпортними зразками виходами бензину за рахунок пониженого газо- та коксоутворення.

Виробництво каталізатора орієнтовано на вітчизняну сировину, переважно каолін Просянівського родовища Дніпропетровської області, і намічено для реалізації на базі цеху з випуску емалей Концерну “Хіммаш” (м. Полтава).

Згідно з Техніко-економічним обґрунтуванням, капітальні вкладення в установку потужністю 10 тис. тонн каталізатора у рік (11 млн. доларів США) окупляться протягом 24-36 місяців.

Каталізатор риформування легких бензинових фракцій, що не вміщує благородних, легкоплавких і летких металів, працює при нижчих температурах і тисках, ніж традиційні каталізатори цього процесу.

Результати випробування каталізатора в риформінгу реальної бензинової фракції зіставимі з результатами риформінгу на промислових платино-ренієвих каталізаторах.

Керівник розробки: д.х.н. Патриляк Любов Казимирівна, тел. (044) 559-71-60.

Додаток до трансмісійних та індустріальних олив, пластичних мастил і мастильно-холодильних рідин для поліпшення їх трибологічних і антиокиснювальних властивостей.

“Етерол-nS” – низка речовин з масовою часткою сульфуру n=5–38 %; не леткі, малонебезпечні прозорі рідини коричневого кольору з кінематичною в’язкістю за 100°С – 3-8 мм2/с, кислотним числом – 2-10 мг КОН/г, температурою спалаху у відкритому тиглі – 265-270°С і температурою займання – 319°С; добре розчинні в оливах.

Поліпшують в’язкісно-температурні, захисні, протизадирні і протизношувальні характеристики мастильних матеріалів в умовах високих навантажень і швидкостей.

За експлуатаційними та екологічними властивостями переважають аналоги на базі жирних кислот олій і їх похідних, і не поступаються високоефективному аналогу “Англамол” фірми Лубризол.

Додаток до антифрикційних мастил для змащування підшипників кочення або ковзання, моторних олив, мастильно-холодильних рідин та інших вузлів тертя промислового обладнання, що експлуатуються в умовах високих температур, навантажень та агресивних середовищ.

“Фосфолідін” – мастилоподібна темно-коричнева речовина з температурою текучості 27-29°С, добре розчиняється у вуглеводнях.

Підвищує на 50 % протизношувальні та у 2,1-2,4 рази антизадирні властивості мастил з одночасним покращенням токсиколого-екологічних і антиокислювальних властивостей, захисної дії щодо чавуну, сталі і міді та зменшенням у 2-6 раз вартості у порівнянні з вітчизняним промисловим діалкілдитіофосфатним додатком ДФ-11.

Антифрикційне мастило, високоефективне у вологих і агресивних середовищах за високих температур і навантажень для обладнання підприємств цегляної, скляної, керамічної та цементної промисловостей.

Мастилоподібна маса з температурою крапання >250°С, межою міцності за 20°С – 800-830 Па, навантаженням зварювання – 7350 Н, критичним навантаженням – 1470-1842 Н, покращеними трибологічними та захисними характеристиками, підвищеною термоокисною стабільністю. За експлуатаційними і екологічними властивостями переважає як вітчизняні ринкові продукти, так і найкращий зарубіжний аналог – Ceran HV фірми Total.

Змащування вузлів тертя металургійного обладнання, що експлуатується в інтервалі від -30°С до +150°С в умовах високих навантажень та можливого впливу агресивних середовищ.

Мастилоподібна маса з температурою крапання >250°С, межою міцності за 20°С – понад 400 Па, підвищеною стабільністю до окиснення за 150°С, покращеними захисними властивостями металевих поверхонь вузлів тертя від корозійних чинників.

За механічною стабільністю, протизношувальними і антизадирними характеристиками мастило переважає вітчизняне мастило “Уніол-2” і найкращі зарубіжні аналоги.

Спеціалізоване мастило для вузлів тертя з підшипниками кочення локомотивів, дизель-поїздів та мотор-вагонного рухомого складу підприємств залізничного транспорту.

Однорідна мастилоподібна маса з температурою крапання 190°С, пенетрацією за 25°С в межах 190-250 м•10-4, в’язкістю за мінус 30°С і середньому градієнті швидкості деформації 10 с-1 – 1650 Па•с, межою міцності за 50°С – 480 Па, навантаженням зварювання – 2600 Н.

Завдяки покращеній механічній стабільності, низькотемпературним, трибологічним, захисним та екологічним властивостям, працездатності в умовах високих навантажень в інтервалі температур від -50°С до +120°С, мастило переважає як товарне мастило ЖРО, так і найкращі аналоги на основі нафтових олив, загущених літійовими милами жирних кислот вартісної рицинової олії.

© 2025 IBOPC NAS of Ukraine